ENGINE

Pistons and Cylinders

5-32

BY Service Manual

© 2009 Yanmar Marine International

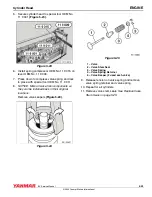

11. Remove the wrist pin retaining rings

Figure 5-48

Figure 5-48

12. Push out the wrist pin. Keep piston and

matched wrist pin together. NOTICE: Pistons

and wrist pins are matched. NEVER mix parts.

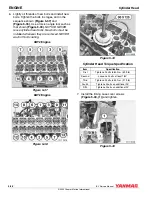

13. Use a piston ring expander (Figure 5-49) to

remove the piston rings, taking care not to

scratch the surface of the piston.

Figure 5-49

Figure 5-49

Inspect Pistons and Piston Rings

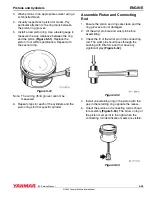

1. Insert new piston rings, one at a time, into the

cylinder. Use a piston with the piston rings

removed to slide the ring squarely into the

cylinder bore. Measure the end gap of each

piston ring (Figure 5-50).

Figure 5-50

Figure 5-50

Note: Measure cylinder bore to ensure it is

within specifications before measuring

piston ring end gap. See Inspect

Cylinder Block on page 5-62.

Specifications

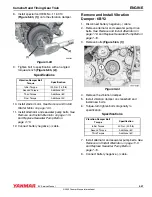

2. Clean piston ring grooves using a piston ring

groove cleaning tool. Follow tool manufacturer’s

instructions for correct operation.

Inspection Item

Standard

Limit

Top Piston

Ring

Side

Clearance

0.12 to 0.16 mm

(0.005 to 0.006 in.)

-

End Gap

0.20 to 0.35 mm

(0.008 to 0.014 in.)

-

Second

Piston

Ring

Side

Clearance

0.07 to 0.11 mm

(0.003 to 0.004 in.)

-

End Gap

0.30 to 0.45 mm

(0.012 to 0.018 in.)

-

Oil Ring

Side

Clearance

Cannot be measured

End Gap

Piston-to-

Cylinder

Clearance

0.15 mm

(0.006 in.)