ENGINE

Cylinder Head

5-24

BY Service Manual

© 2009 Yanmar Marine International

Clean Cylinder Head Components

Thoroughly clean all components using a

non-metallic brush and an appropriate solvent.

Each part must be free of carbon, metal filings and

other debris.

Pressure Test the Cylinder Head

1. Remove and disassemble cylinder head. See

Disassemble Cylinder Head on page 5-22.

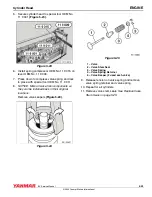

Figure 5-26

Figure 5-26

Note: Special tool OEM No. 11 6 407 consists

of twelve screws for mounting special

tools OEM No. 11 6 401 to the cylinder

head. If OEM No. 11 6 407 is not

available, use the old cylinder head bolts

to secure special tool OEM No. 11 6 401.

2. Seal off all coolant openings using special tool

OEM No. 11 6 400.

Note: OEM No. 11 6 400 consists of 11 6 401,

11 6 406, 11 6 407 and 11 6 408.

3. Connect air source to cylinder head and

immerse in water bath. Apply pressure and

adjust to 4.5 bar (65 psi) (Figure 5-27).

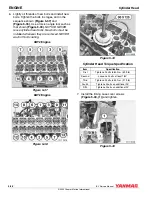

Figure 5-27

Figure 5-27

Note: Reduce surface tension of water used for

test with a few drops of detergent.

4. Inspect cylinder head for discharge of bubbles

indicating a crack in the casting.

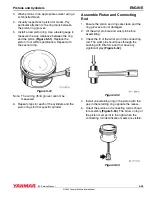

Inspect Cylinder Head Components

Clean all gasket material, sealant and carbon from

components. Use a suitable solvent and a

soft-bristle brush to clean parts.

Visually inspect parts. Replace any parts that are

obviously discolored, heavily pitted or otherwise

damaged. Discard any part that does not meet its

specified limit. NOTICE: Any part which is found

defective as a result of inspection or any part

whose measured value does not satisfy the

standard or limit must be replaced.

NOTICE: Mark all valve train components so they

can be installed in their original locations.

Note: Record all measurements taken during

inspection.