53

4. Operating procedure

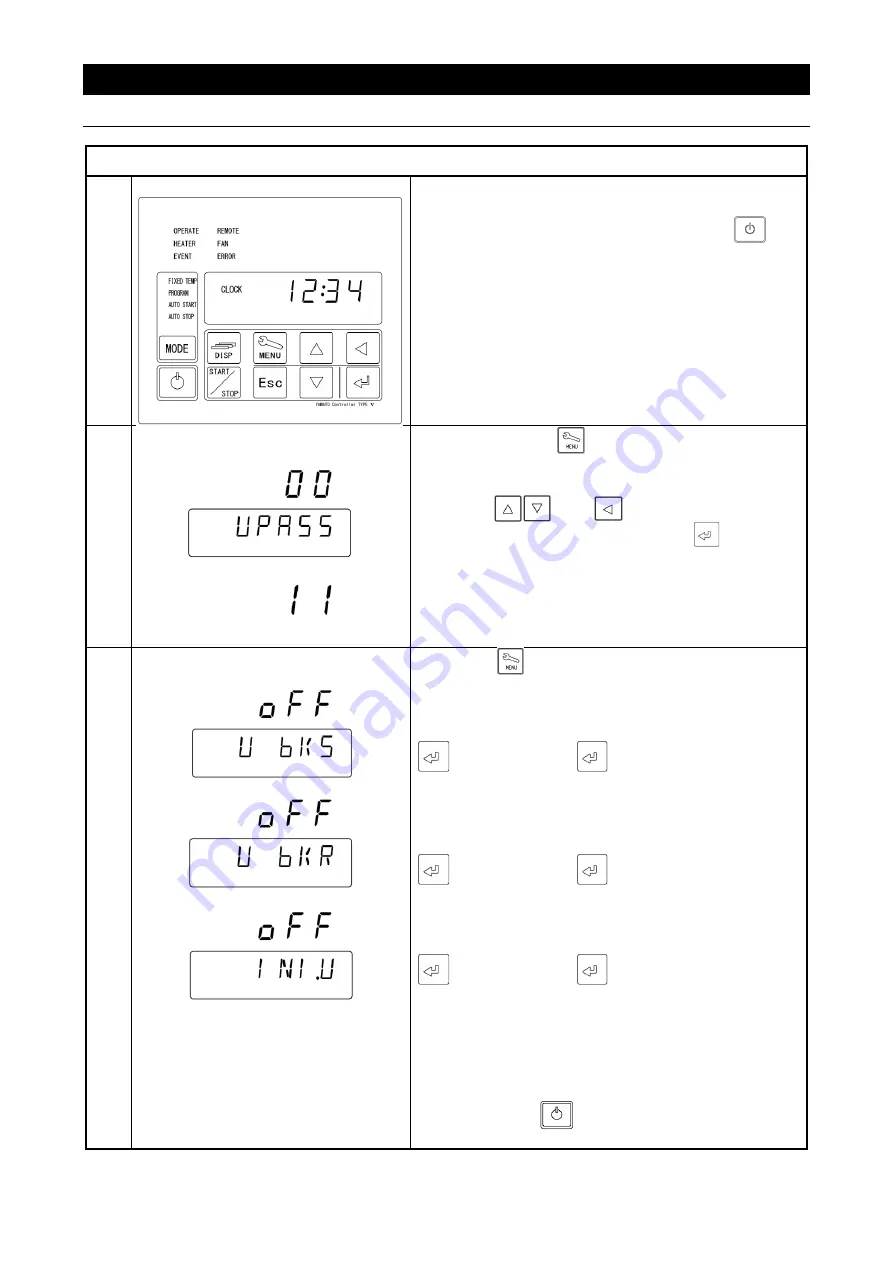

Backup data saving / reading out / resetting

※

Back up, read out and reset controller for various setting information.

1 Turning the controller power off

Turn the ELB on the right side of the main unit [ON(

|

)].

The Bottom screen will show the current time.

While the unit is being operated, press the

key

longer to turn the controller power off.

2 Enter password.

↓

③

Press and hold

key.

Show [

UPASS

] on Bottom Screen and [

00

] flashing

on Top Screen.

④

Press

and

keys to enter password

“11” on Top Screen and press

key (The

password is fixed to “11”.).

3 Save and read out and/or reset

setting information.

①

Press

key few times and show following

items on Bottom Screen, respectively:

U BKS

:

Back various setting information up.

key

「

RUN

」

(flash)

→

key

「

OFF

」

(illuminate)

U BKR

:

Read backup setting information out.

key

「

RUN

」

(flash)

→

key

「

OFF

」

(illuminate)

INI

.

U

:

Initialize various setting information.

key

「

RUN

」

(flash)

→

key

「

OFF

」

(illuminate)

※

Various setting information will be included

registered programs, temperature offset value and

other data such as key lock mode, calibration

offset, recovery mode and so forth.

②

Pressing the

key longer will return to the time

display screen.