11

3

2

1

b

1

a

4

a

4

No.

N a m e

①

O-ring

②

Adaptor of level difference connector

③

O-ring

④

Rotary connector

No.

N a m e

①

Packing

②

Filter

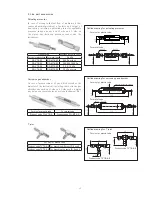

Fig.1

Fig.2

Installation of rotary connector

・ When you change piping connector from straight type to

rotary loose or rotary lock type, refer to the assembly drawing

on the right.

1. After cleaning well around connector area, take off the

straight type connector by the spanner. Because of

preventing intrusion of dust in internal instrument at the

time taking off.

2. The O-ring ① of the assembly drawing has been installed

already on the instrument body.

The O-ring ③ has been installed on the adaptor of level

difference connector ② .

3. Install the adaptor of level difference connector to

mainbody to tighten the part Ⓑ by the spanner in advance.

Then tighten ground Ⓐ of level difference connector by

spanner. Install the rotary connector to both instrument

body and the level difference adaptor.

4. After installing, make sure that connector part is turned.

In case of lock type, make sure that connector part is not

turned.

However, in piping, loose the head and move the

connector where it is desired to be located and should be

tightened again to fi x.

Replacement of air fi lter

・ In case of using model with air fi lter (MS65F), depending on

amount of work, conduct disassembly and clean out once in

2 years periodically and replace fi lters and packings with new

ones.

・ Filters are constructed as shown in Fig.1.

<How to change>

1. Loosen and take out four assembly screws

a

from the

instrument body, and disassemble fi lter unit.

2. Remove the used fi lters ② and packings ① from case

b

,

and clean out the inner surfaces of case

b

and

c

.

3. Replace new packings and filters with refer to Fig.2.

Packings should be fi t correctly into the grooves on both

side of case

b

.

Next, place new fi lters onto both sides of case

b

. (There

are no distinction between the front and the back in

packing and fi lter either.)

4. Then put case

b

on top of case

c

together as to coincide the position of the

through-hole on case

b

with the air hole

on case

c

correctly. (refer to Fig.2)

5. Place the instrument body on top of case

b

piled with case

c

.

Make sure that the relation of position

between the installing leg of case

c

and

the connectors on the instrument body

are the same as that Fig.2 shows. And

also make sure that convex parts under

the instrument body are fi t into the hollow

parts (spot facings) on each corner of case

b

.

6. Insert four assembly screws

a

into screw-

holes as shown in Fig.1 and tighten the

instrument body and cases

b

c

fi rmly.