6

5. Compatibility of connectors

The piping connector of Manostar switch MS65, MS65F, WO81, and WO70 are not compatible with each

other.Make sure to use the dedicated connectors of Manostar switch MS65, MS65F.

6. Caution of piping

a)

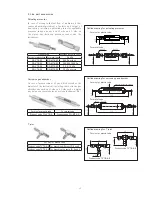

Prohibition of common piping

Piping each of pressure detectors and pressure

receiving instruments tube exclusively dedicated

for it, and do not connect the piping commonly

with the adjacent system as shown in the right

fi gure.

Common piping causes measurement error because

the pressure of each system interferes.

b)

Prevention of clogged piping due to drain

・ If drain remains within the line, it causes measurement error. Be

sure to install the pressure receiving instrument above the pressure

outlet port of the pressure detector and arrange the line so that the

drain water should not remain in the slack piping.

・ If the arrangement mentioned above in not possible, install a drain

tank within the line as shown in the right fi gure and clean it once in

a while.

・ After the cleaning of the tank, check that the air tightness is fully

kept.

c)

Measurement of high temperature gases

In the pressure measurement of high temperature gas, use the pressure detector (pitot tube) made of

the heat-proof metal (such as stainless steel), and connect it with the pressure receiving instrument

through a metal tube which is long enough to cool down the high temperature gas.

d) Errors caused by long distance piping

The speed of response is delayed when the product is used for remote monitoring.

In such application, the I.D. of the connection tube should be as large as possible.

The time constant is almost inversely proportional to the inner cross sectional area of the piping.

If the piping conditions of the high and low pressure side are signifi cantly different, the difference in the

piping resistance between high and low puressure side causes the difference in pressure transmission

time, and the measurement becomes inaccurate.

7. Installation position

㻵㼚㼐㼑㼜㼑㼚㼐㼑㼚㼠㻌㼜㼕㼜㼕㼚㼓䕿㻌

ᵮᵿᶑᶑᵿᶅᶃᶕᵿᶗ

ᵮᵿᶑᶑᵿᶅᶃᶕᵿᶗ

ᵰᶍᶍᶋᴾᵠ

ᵰᶍᶍᶋᴾᵟ

ᵰᶍᶍᶋᴾᵠ

ᵰᶍᶍᶋᴾᵟ

ᵫᵱᵔᵓ

ᵫᵱᵔᵓ

ᵫᵱᵔᵓ

ᵫᵱᵔᵓ

㻯㼛㼙㼙㼛㼚㻌㼜㼕㼜㼕㼚㼓㽢㻌

Drain

Drain

tank

Switch

㻵㼚㼟㼠㼍㼘㼘㼍㼠㼕㼛㼚㻌㼐㼕㼍㼓㼞㼍㼙㻌㼛㼒㻌㼐㼞㼍㼕㼚㻌㼠㼍㼚㼗

In ordering out of above mentioned installation position, please order us or our agency beforehand. It must be

adjusted before the factory shipment.

ᵧᶌᶑᶒᵿᶊᶊᵿᶒᶇᶍᶌ

ᶎᶍᶑᶇᶒᶇᶍᶌᴾᵿᶌᶅᶊᶃ

ᶂᶍᶕᶌᶕᵿᶐᶂᴾᵏᵑᵓᴾᶟ

ᵢᶍᶕᶌᶕᵿᶐᶂᴾᶆᶍᶐᶇᶘᶍᶌᶒᵿᶊ

ᵴᶃᶐᶒᶇᶁᵿᶊ

ᵴᶃᶐᶒᶇᶁᵿᶊ

ᵦᶍᶐᶇᶘᶍᶌᶒᵿᶊᴾ

ᵿ

ᶀ

ᵏᵎᴾỰ

ᵏᵎᴾỰ

ᵦᶍᶐᶇᶘᶍᶌᶒᵿᶊᴾᶎᶊᵿᶌᶃ

ᵴᶃᶐᶒᶇᶁᵿᶊᴾᵮᶊᵿᶌᶃᴾ

ᵤᶍᶊᶊᶍᶕᶇᶌᶅᴾᶇᶌᶑᶒᵿᶊᶊᵿᶒᶇᶍᶌᴾᶎᶍᶑᶇᶒᶇᶍᶌᴾᶇᶑᴾᵿᶔᵿᶇᶊᵿᶀᶊᶃ

ᶀ

ᵱᶒᵿᶌᶂᵿᶐᶂᴾᶇᶌᶑᶒᵿᶊᶊᵿᶒᶇᶍᶌᴾᶎᶍᶑᶇᶒᶇᶍᶌ

ᵱᶎᶃᶁᶇᶄᶇᶃᶂᴾᶇᶌᶑᶒᵿᶊᶊᵿᶒᶇᶍᶌᴾᶎᶍᶑᶇᶒᶇᶍᶌ

ᵿ

ᵭᶌᴾᶇᶌᶑᶒᵿᶊᶊᵿᶒᶇᶍᶌᴾᶎᵿᶌᶃᶊᵊᴾᶄᶍᶊᶊᶍᶕᶇᶌᶅ

ᶎᶍᶑᶇᶒᶇᶍᶌᴾᶇᶑᴾᵿᶔᵿᶇᶊᵿᶀᶊᶃᵌ

㻿㼠㼍㼚㼐㼍㼞㼐㻌㼕㼚㼟㼠㼍㼘㼘㼍㼠㼕㼛㼚㻌㼜㼛㼟㼕㼠㼕㼛㼚㻌㼕㼟㻌㼒㼞㼛㼙㻌㼡㼜㼣㼍㼞㼐㻌㼔㼛㼞㼕㼦㼛㼚㼠㼍㼘㻌㼠㼛㻌㼢㼑㼞㼠㼕㼏㼍㼘

ᵟᶊᶊᴾᶐᵿᶌᶅᶃ