10

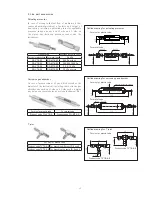

VL rotary loose connector type

VK rotary lock connector type

The adaptor of level difference

connector for rotary type

Terminal cover set

Dial cover set

MTW straight connector type (double ring joint)

MK rotary lock connector type

ML rotary loose connector type

MT straight connector type

Filter set

VT straight connector type

Product code KGA65VT

Product code KGA65VRL

Product code KGA65VRK

Product code KGA65ADPA

Product code KGA65MT

Product code KGA65MRL

This connector can be rotated freely

and fi xed at any position.

This connector can be rotated freely

and fi xed at any position.

Product code TCA-65

Product code KGA65MTW-S

Product code AFS65

Two sets of fi lter, Two sets of packing

Product code TCLAMPA-65

This cover avoids trouble that

someone set dial carelessly.

For stainless tube made from stainless steel

This connector can be rotated freely

after piping.

4. About measured gas and contact failure

a) Corrosive gas

If the gas to be measured contains corrosive gases (nitric acid, hydrogen sulfide, sulfurous acid,

ammonia, chlorine, and so on), they may cause electrical contact failure or corrosion of internal

mechanism, which leads to malfunction of the switch. Do not use the switch for the gases containing

high humid air because in such gases, the arc generated by opening/ closing the contact produces nitric

acid, and it may also cause electrical contact failure or malfunction of switches.

b) Silicone gas

If the gas to be measured contains silicon produced from silicon (contained in oil, grease, filling agent,

and so on), the gas produced by arc, generates by opening/ closing the contact, accumulates on the

contact surface and causes contact failure. Take corrective measures such as the removal of the gas

source or arc suppression.

c) Dust and organic gas

The micro switch used in a Manostar switch is installed in the positive pressure measurement chamber.

The gas to be measured can easily flows into the chamber, thus, the composition of the gas largely

affects the formation of the film. In addition, the dust contained in the gas to be measured can adhere to

the contact surface and be changed into carbide caused the contact failure by the arc generated when

the contact is opened or closed. Therefore, pay attention to the measurement environment as well.

(Even with gold alloy contact, be careful about the dust.)

!

Caution

As the opening/ closing frequency of the contact increases, wear dust from the contact

increases. This wear dust accumulates between the contacts to increase the contact resistance

and causes the malfunction in the load circuit.

In particular, the surrounding where there exists continuous vibration and impact will be most

likely to cause contact failure due to worn powder.

Ⅵ. ACCESSORIES

1. Accessory for MS65 (for MS65, MS65F and MS65R)

This connector can be rotated freely

after piping.

Product code KGA65MRK