xvi

Outboard Rigging Guide - 2001

General Rigging Information

Fuel Pump/Fuel System Testing

When a fuel starvation problem is suspected (e.g.,

engine hesitation or engine stopping), perform the

following fuel system test:

Tool Required:

1 Vacuum Gauge

1 “T” Fitting (P/N 6E5-24378-00-00)

1 2” Clear Fuel Hose (5/16” or 8 mm ID)

1 Long Fuel Hose (10”-15”)

2 Hose Clamps or Quick Ties

Procedure:

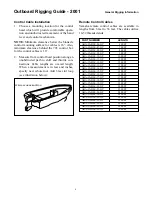

1.

Connect the piece of clear fuel hose to a side

barb of the “T” fitting (1).

2.

Connect the short piece of clear fuel hose to

the fuel check valve leading from the fuel fil-

ter. If a check valve does not exist, connect

the clear fuel hose directly to the fuel filter

(see illustration below).

3.

Check the vacuum gauge reading after run-

ning the engine long enough to stabilize at

full power.

IMPORTANT: From idle rpm to WOT rpm, the

vacuum is not to exceed 4.5 inches for up to

200hp engines and 2.6L, 0X66 engines. The vac-

uum is not to exceed 6.0 inches for engines

greater than 200hp and all 3.1L, 0X66 engines

including the V200 3.1L EFI.

An anti-siphon valve (required if the fuel system

drops below the top of the fuel tank) will cause a

1.5 to 2.5 inches increase in vacuum.

Results:

High Vacuum - Move the “T” fitting to the fuel

filter outlet (2) and retest. Continue to the fuel fil-

ter inlet (3) and along the remaining fuel filter

system until a large drop in vacuum locates the

problem.

1.

A good clean water separator fuel filter will

increase vacuum about 0.5 inch.

2.

Small internal passages inside a fuel selector

valve, fuel tank pickup, or fuel line fittings

may cause excessive fuel restriction and high

vacuum.

3.

Unstable and slowly rising vacuum readings

(especially with a full tank of fuel) usually

indicates a restricted vent line.

NOTE: If you have a low vacuum reading at

WOT rpm - 1 in Hg ~ 3 in Hg, check for air leaks.

NOTE: Bubbles in the clear fuel line section indi-

cate an air leak; making for an inaccurate vacuum

test. Check all fittings for tightened clamps and a

tight fuel filter.

NOTE: On EFI engines, install a fuel rail pres-

sure gauge.

Summary of Contents for T8

Page 2: ......

Page 9: ......

Page 35: ......

Page 37: ......

Page 61: ......

Page 63: ......

Page 65: ...2 2 Outboard Rigging Guide 2001 Engine Mounting Dimensions...

Page 67: ...2 4 Outboard Rigging Guide 2001 Engine Mounting Dimensions...

Page 71: ...2 8 Outboard Rigging Guide 2001 Transom Mounting Patterns 25HP 2 Cylinder...

Page 72: ...2 9 Outboard Rigging Guide 2001 Transom Mounting Patterns 25X3 3 Cyl 30HP 40HP Manual Tilt...

Page 109: ......

Page 111: ......

Page 128: ...3 17 Outboard Rigging Guide 2001 Switch Panels Oil Lamp Panel Assembly T9 9ELR 6G8 83530 00 00...

Page 155: ...3 44 Outboard Rigging Guide 2001 Boat Wiring Diagrams T9 9 with 703 Control...

Page 156: ...3 45 Outboard Rigging Guide 2001 T9 9 with Switch Panel...

Page 177: ...3 66 Outboard Rigging Guide 2001 After Market Dash Wiring...

Page 178: ...3 67 Outboard Rigging Guide 2001 COMPLETE BOAT WIRING DIAGRAMS 70 90HP F80 F115...

Page 179: ...3 68 Outboard Rigging Guide 2001 Complete Boat Wiring Diagrams V4 V6 Single Engine...

Page 180: ...3 69 Outboard Rigging Guide 2001 Complete Boat Wiring Diagrams V4 V6 Single Engine Cont d...

Page 181: ...3 70 Outboard Rigging Guide 2001 Complete Boat Wiring Diagrams V4 V6 F115 Dual Engine...

Page 182: ...3 71 Outboard Rigging Guide 2001 Complete Boat Wiring Diagrams V4 V6 F115 Dual Engine Cont d...

Page 183: ...3 72 Outboard Rigging Guide 2001 Complete Boat Wiring Diagrams V6 HPDI Single Engine...

Page 184: ...3 73 Outboard Rigging Guide 2001 Complete Boat Wiring Diagrams V6 HPDI Dual Engine...

Page 185: ......

Page 187: ......

Page 236: ......

Page 242: ...5 5 Outboard Rigging Guide 2001 Tachometer Digital Multi function Tachometer...

Page 359: ...6C 2 Outboard Rigging Guide 2001 E FEATURES...

Page 376: ...7 15 Outboard Rigging Guide 2001 F15 F25 Remote Control Attach Kit REMOVAL...

Page 406: ...NOTES...

Page 407: ...NOTES...

Page 418: ...Outboards 6X1 DUAL STATION SYSTEM INSTALLATION MANUAL YAMAHA MOTOR CO LTD 6X1 28199 Y2 10A 1...

Page 423: ...10A 6 GENERAL INFORMATION WIRING AND COMPONENT PARTS Single engine system Second station...

Page 424: ...10A 7 Twin engine system Second station...

Page 453: ...WIRING DIAGRAM FIRST STATION Single engine 10A 36...

Page 454: ...SECOND STATION Single engine 10A 37...

Page 455: ...10A 38...

Page 456: ...10A 39...

Page 457: ...Outboards 6X1 DUAL STATION SYSTEM SERVICE GUIDE 10B 1...

Page 460: ...10B 4...

Page 462: ...10B 6 Outboard Rigging Guide 2001 EXTERNAL VIEW OUTLINE OF FEATURES...

Page 495: ...10B 39 Outboard Rigging Guide 2001...

Page 496: ...10B 40 Outboard Rigging Guide 2001...