Maintenance

95

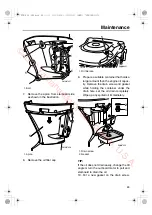

to install the thrust washer before in-

stalling the propeller. Otherwise, the

lower case and propeller boss could

be damaged.

[ECM01882]

3. Install the spacer, washer, and propeller

nut. Tighten the propeller nut to the

specified torque.

TIP:

Make sure to align the protrusions on the

spacer with the cutout areas of the propeller.

4. Align the propeller nut slot with the pro-

peller shaft hole. Insert a new cotter pin

in the hole and bend the cotter pin ends.

NOTICE:

Do not reuse the cotter pin.

Otherwise, the propeller can come off

during operation.

[ECM01892]

TIP:

If the propeller nut slot does not align with the

propeller shaft hole after tightening the pro-

peller nut to the specified torque, tighten the

nut further to align the slot with the hole.

EMU41193

Changing gear oil

WARNING

EWM02531

Make sure that the outboard motor is

mounted securely to the transom or a

stable stand. You could be severely in-

jured if the outboard motor falls on you.

Never get under the lower unit while it

is tilted. Severe injury could occur if the

outboard motor accidentally falls.

Before filling the lower unit with gear oil, the

outboard motor must be placed in a vertical

position. If you are not able to place the out-

board motor in a vertical position, have a

Yamaha dealer change the gear oil.

1. Tilt the outboard motor so that the gear

oil drain screw is at the lowest point pos-

sible.

2. Place a suitable container under the

gear case.

3. Loosen the bolt, and then remove the

cooling water inlet covers on both sides

of the gear case.

1. Cotter pin

2. Propeller nut

3. Washer

4. Spacer

5. Propeller

6. Thrust washer

Propeller nut tightening torque:

54 Nm (5.51 kgf-m, 39.8 ft-lb)

4 3

2

1

5

6

ZMU07187

1. Cotter pin

1

ZMU06956

6CE-9-36-1E0.book 95 ページ 2014年11月28日 金曜日 午後2時55分

©

2019 Yamaha Motor Corporation, U.S.A.