May 2016

P 11

HD23F1JP0E8

da Vinci

Jr.1.0 Pro

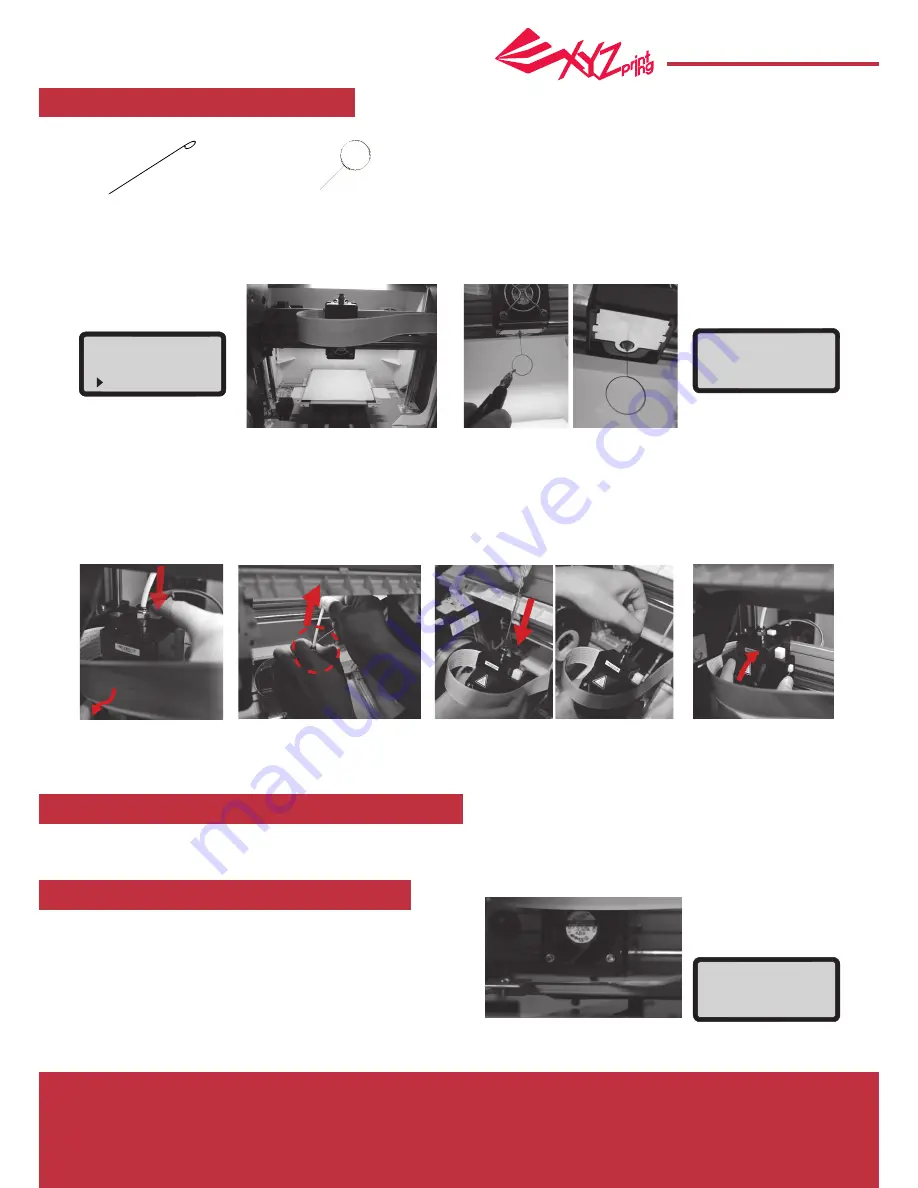

CLEAN NOZZLE

Z OFFSET (adjust the printer module)

Z OFFSET settings adjustment

The user may use the Z OFFSET function to adjust the gap between the printing nozzle and the printing bed.

Caution: This printer has already been tested and adjusted to the optimal gap between the printing nozzle and printing bed before

shipping. We recommend recording the original settings before carrying out any adjustments.

UTILITIES

Over time, carbon deposits or filament dust buildup in the nozzle may decrease its performance. It is advised to clean the nozzle

after every 25 hours of printing.

Also, if the print bed calibration shows “ERR” or if there is any residue on your prints, you may try to clean the nozzle.

To clean the nozzle:

3.Hold the cleaning wire with the

pliers, and carefully pass the wire

through the nozzle openning.

1.Select "YES" to begin.

4.Select "OK" to return.

2.Wait until the extruder heats up and

moves to the front, and the screen

shows “READY FOR CLEAN”

1.The recommended distance between the nozzle and print bed

(with bed tape securely fastened) is 0.3mm.

This should allow two sheets of copy paper to be drawn out

smoothly but six sheets of copy paper cannot be passed.

2.Increase/decrease the value based on a scale of 0.05mm.

Increasing the value will increase the gap between the print module and print bed by 0.05mm

Decreasing the value will also decrease the gap between the print module and print bed by 0.05mm

+ [ ^ ]

Z OFFSET 0.1 mm

─ [ v ]

[OK] TO SAVE

If the cleaning cycle does not unclog the extruder, try cleaning the feeding path by following the steps below.

1.Unload filament correctly (refer to “UNLOAD FILAMENT”).

2.Move the extruder and the print bed to the home position by using the HOME AXES function.

3.Activate “UNLOAD FILAMENT” again and wait until the extruder is heat up to 150

℃

. (Care should be taken during the operation to

avoid potential burn injuries.)

CLEAN NOZZLE

ARE YOU SURE ?

NO

YES

CLEAN NOZZLE

READY FOR CLEAN

[ OK ] TO RETURN

4.Press the white button

at the back of the

extruder to release it.

5.Lightly press the spring around

the feed hole and remove the

filament guide tube (do not

disconnect the white flat cable)

7.After cleaning the feeding

path, reinstall the guide tube

to the top of the extruder and

install the extruder to the

bracket.

6.Insert the thick cleaning wire into the

feeding path all the way down and “floss”

the inside of the nozzle to pull the residue

out.

A.Feeding Path Cleaning Pin

B.Cleaner Wire