May 2016

P 12

HD23F1JP0E8

da Vinci

Jr.1.0 Pro

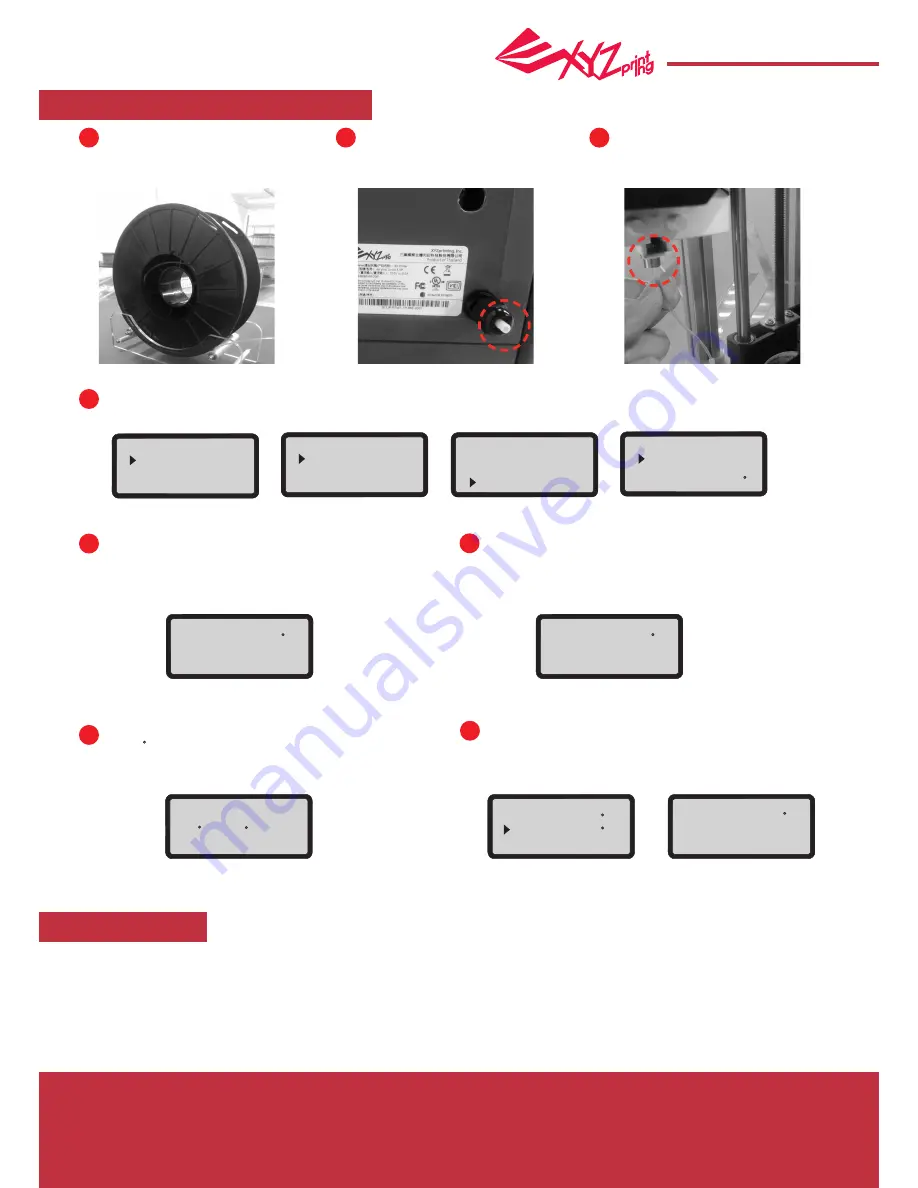

If you’re using third party filaments,

please secure the filament using

the holder.

Load the filament from the back

of the printer.

In the printer, insert the filament into the

feed port. Open the release arm so that

the front tip of the filament can be

properly inserted into the feed module.

Load the filament function of the printer function. When the panel displays:

"USE XYZPRINTING SPOOL? ", select "NO "> "APPLY SETTING " (and enter temperature settings).

Adjust the nozzle temperature according to the

supplier’s recommendations.

Use the left

【<】

and right

【>】

buttons to select

the digits. Use the up

【

<

】

and down

【

<

】

buttons to increase or lower the number.

The recommended printing temperature range is 190

to 230 C. The screen would display a temperature

range reminder if the temperature settings exceed this

recommended range.

* Hang the spool on the filament spool holder prepared by yourself, we recommend use the support bracket to avoid collaps

-

ing when printing.

* Print quality cannot be guaranteed if filaments from other brands are used instead.

* The warranty does not cover stuck filaments, product failure, damage or defects resulting from the use of other brand’s fila

-

ment or 3rd party slicing software.

The user may go to SETTING

>USER FILAMENT

>NOZZLE to set the nozzle temperature.

Once temperature settings have been completed,

press "

OK

" to complete the settings.

1

2

3

5

7

8

6

4

REMARK

USE XYZPRINTING

SPOOL?

YES

NO

USER FILAMENT

APPLY SETTING

--------------------------

NOZZLE 200 C

NOZZLE 2 [ 1 ] 0 C

[ < ] , [ > ]

[ OK ]

TO CONTINUE

<

>

NOZZLE 2 [ 1 ] 0 C

[ < ] , [ > ]

[ OK ]

TO CONTINUE

<

>

INVALID VALUE

MIN / MAX

190 C / 230 C

[ OK ] TO RETURN

USER FILAMENT

NOZZLE 210 C

UNLOAD 190 C

UTILITIES

CHANGE SPOOL

HOME AXES

JOG MODE

NOZZLE 2 [ 1 ] 0 C

[ < ] , [ > ]

[ OK ]

TO CONTINUE

<

>

OPEN FILAMENT

CHANGE SPOOL

LOAD FILAMENT

UNLOAD FILAMENT

Install Compatible filament