May 2016

P 7

HD23F1JP0E8

da Vinci

Jr.1.0 Pro

LOAD FILAMENT

Then load filament using the control panel on the printer…

UNLOAD FILAMENT

First unload filament using the control panel on the printer…

1

1

Select "UTILITIES" > "CHANGE SPOOL" > "LOAD FILAMENT" > "YES".

Select "UTILITIES" > "CHANGE SPOOL" > "UNLOAD FILAMENT".

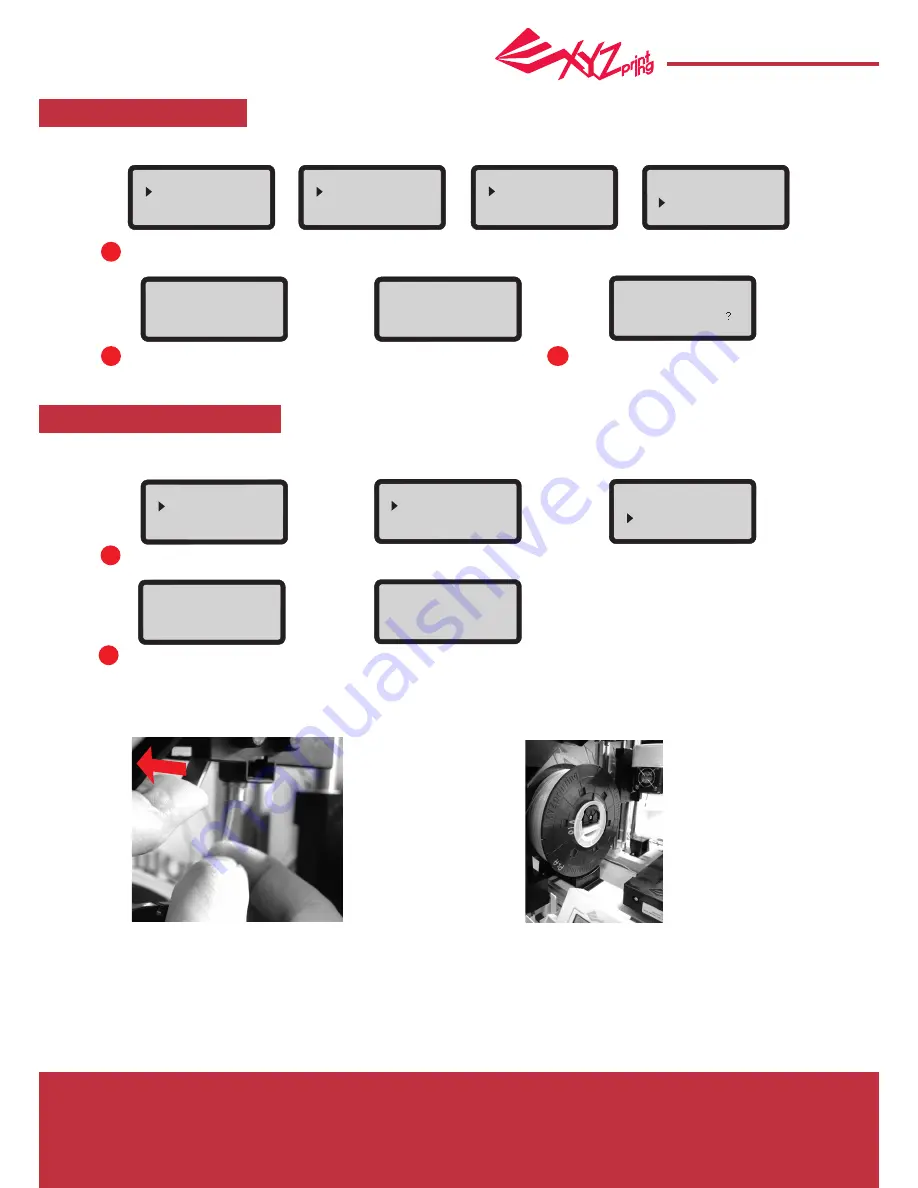

First open the release arm and then pull out the filament

with spool axle rings. Arrange it properly for later use.

2

2

Wait for the extruder to heat up and load

filament.

Wait for the extruder to heat up and unload filament. Press "OK" to pull out filament.

3

Check if the nozzle outputs filament and

press "OK" to go back to main menu.

LOAD FILAMENT

EXTRUDER HEATING

TEMPERATURE 210

∘

C

PLEASE WAIT

LOAD FILAMENT

EXTRUDER HEATING

TEMPERATURE 210

∘

C

PLEASE WAIT

LOADING

PLEASE WAIT

UNLOADING

PLEASE WAIT

[ OK ] TO RETURN

UTILITIES

CHANGE SPOOL

HOME AXES

JOG MODE

CHANGE SPOOL

LOAD FILAMENT

UNLOAD FILAMENT

CHECK FILAMENT

OUT FROM NOZZLE

[

<

]

TO RETRY

[ OK ]

TO RETURN

DA VINCI

Jr. Pro

BUILD FROM CARD

UTILITIES

SETTINGS

When finishing "UNLOAD FILAMENT"

Unload Filament

Note: Always implement the "UNLOAD FILAMENT" function when replacing

the cartridge in order to ensure proper removal of the filament. Cutting

filament too closely to the print head may result in residual filament

blocking and causing damage to your print head.

UTILITIES

CHANGE SPOOL

HOME AXES

JOG MODE

USE XYZPRINTING

SPOOL?

YES

NO

DA VINCI

Jr. Pro

UTILITIES

SETTINGS

INFO

CHANGE SPOOL

LOAD FILAMENT

UNLOAD FILAMENT