S-75

V3307-DI-T-E2B, WSM

ENGINE

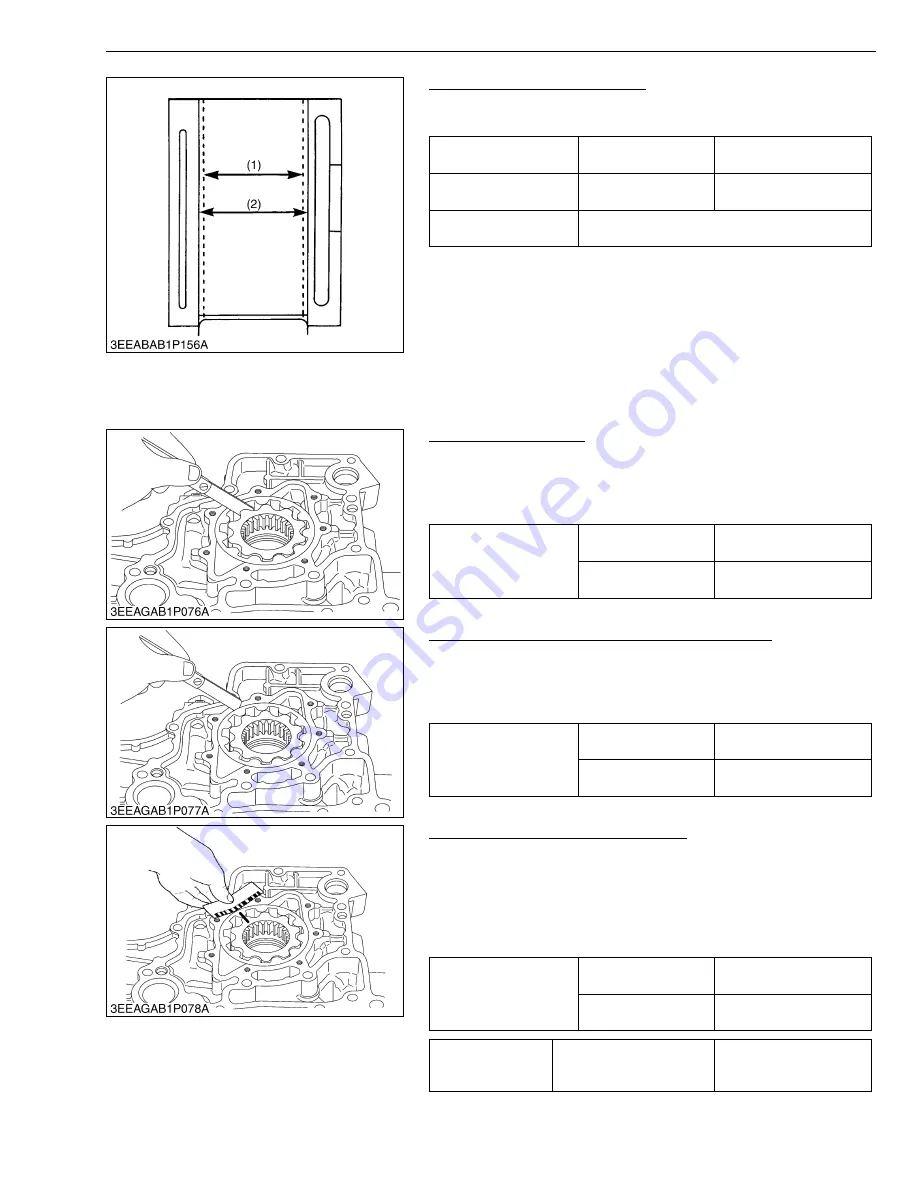

Correcting Cylinder (Oversize)

1. When the cylinder is worn beyond the allowable limit, bore and

hone it to the specified dimension.

2. Replace the piston and piston rings with oversize 0.5 mm (0.02

in.) ones.

NOTE

Q

• When the oversize cylinder is worn beyond the allowable

limit, replace the cylinder block with a new one.

W10344480

(6) Oil Pump

Rotor Lobe Clearance

1. Measure the clearance between lobes of the inner rotor and the

outer rotor with a feeler gauge.

2. If the clearance exceeds the allowable limit, replace the oil pump

rotor assembly.

W1071254

Clearance between Outer Rotor and Pump Body

1. Measure the clearance between the outer rotor and the pump

body with a feeler gauge.

2. If the clearance exceeds the allowable limit, replace the oil pump

rotor assembly.

W1071334

Clearance between Rotor and Cover

1. Put a strip of plastigage onto the rotor face with grease.

2. Install the cover and tighten the screws with the specified torque.

3. Remove the cover carefully, and measure the amount of the

flattening with the scale and get the clearance.

4. If the clearance exceeds the allowable limit, replace oil pump

rotor assembly and the cover.

W1148218

Cylinder I.D. (Oversize)

Factory spec.

94.500 to 94.522 mm

3.7205 to 3.7213 in.

Maximum wear

Allowable limit

94.65 mm

3.726 in.

Finishing

Hone to 2.2 to 3.0

μ

m Rz

(0.000087 to 0.00011 in. Rz)

∇∇∇.

(1) Cylinder I.D. (Before Correction)

(2) Cylinder I.D. (Oversize)

Clearance between

inner rotor and outer

rotor

Factory spec.

0.030 to 0.090 mm

0.0012 to 0.0035 in.

Allowable limit

0.30 mm

0.012 in.

Clearance between

outer rotor and pump

body

Factory spec.

0.100 to 0.184 mm

0.00394 to 0.00724 in.

Allowable limit

0.30 mm

0.012 in.

Clearance between rotor

and cover

Factory spec.

0.025 to 0.075 mm

0.00099 to 0.0029 in.

Allowable limit

0.225 mm

0.00886 in.

Tightening torque

Oil pump cover screw

7.9 to 9.3 N·m

0.80 to 0.95 kgf·m

5.8 to 6.8 lbf·ft

KiSC issued 01, 2009 A