38

03/2009

8.4

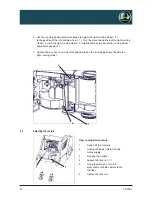

Adjusting the tension roller

The tension roller automatically controls the abrasive belt to ensure that the belt runs

centrically on the sanding roller. If the automatic centering control deteriorates in the

course of operation, the tension roller has to be readjusted.

Caution! Danger of injury!

The abrasive belt shall only be adjusted by qualified personnel since the adjustment

has to be performed on the running machine with opened sanding roller cover

(in accordance with BGV A1, § 41 Rüst-, Instandhaltungsarbeiten, German Occupational

Health and Safety Association on setting up and maintenance work).

Caution!

Wear protective goggles and avoid loose clothes when carrying out this adjustment work.

How to adjust the tension roller:

Caution!

Before carrying out the steps described in the following, make sure that the main lifting

lever is folded backwards to raise the sanding roller from the floor.

1. Make sure that the motor switch is in the off position and the power cable is unplugged

from the mains supply.

2. Open the belt cover.

3. Insert an abrasive belt.

4. Fold the tension lever backwards to take up abrasive belt slack.

5. Loosen the retaining nut ( 1 ).

6. Connect the machine to the mains supply (see chapter 7.8).

7. Switch on the machine to level

1

.

8. Turning the adjustment nuts ( 2 ) moves the tension roller which affects the abrasive belt

travel. Adjust the position of the abrasive belt until it runs in the middle of the sanding roller.

9. Switch off the machine and unplug the cable from the mains supply.

10. Tighten the adjustment nuts ( 2 ).

11. Close the belt cover.

1

2