RANGES &

& R

RANGETOPS

Troubleshooting Guide

5-10

PROBLEM

POSSIBLE CAUSE

TEST / ACTION

FF. DELAYED IGNITION OF

OVEN BROILER

GG. RUSHING NOISE FROM

OVEN BROILER BURNER

HH. CONVECTION FAN DOES

NOT COME ON WHEN

SWITCH IS TURNED ON

II. CONVECTION FAN DOES

NOT SHUT OFF WHEN

DOOR IS OPEN

JJ. PROBLEMS ASSOCIATED

WITH THE OVEN LIGHT

KK. SURFACE BURNER RINGS

TURN RAINBOW COLORS

LL. RISER IS DISCOLORED OR

BURNED

Igniter bracket bent

Defective glow coil igniter

Defective bi-metal valve

Bent orifice bracket holder

Blockage in venturi or orifice

Bent orifice bracket holder

Back Lighting situation

Oven broiler is on

Loose connection

Defective fan panel switch

Defective fan motor

Defective fan relay

No Power

Fan switch in “COOL” position

Defective fan door switch

Defective fan relay

Defective fan panel switch

Defective light bulb

Loose or disconnected wire connection in

the wiring circuit

Defective light panel switch

Defective light socket

No power

Discoloration from heat

Discoloration from heat, caused by flames

licking out from large pots at rear burners.

Straighten and position

Replace if not drawing 3.3 to 3.6 amps.

Replace if not drawing 3.03 to 3.3 VAC.

Straighten so that gas jet is aimed straight down

venturi tube, replace if necessary.

Clear as necessary

Straighten so that gas jet is aimed straight down

venturi tube, replace if necessary.

Gas is burning between screens or in box.

Broiler needs to be replaced

Fan does not function during broil

Check all components in circuit. See wiring dia-

gram.

Check for continuity and replace if defective

Check for continuity and replace if defective

Check for continuity and replace if defective

Check outlet and circuit breaker

This is normal operation. Instruct customer

Check for continuity and replace if defective

Check for continuity and replace if defective

Check for continuity and replace if defective

Check light bulb and replace if necessary

Check for voltage at the light sockets

Check light circuit with wiring diagram

Check continuity of the light socket

Check outlet and circuit breaker

This is normal after repeated use

This is normal. Always test cleaning solutions

on a non conspicuous stainless steel spot

before attempting to clean.

Summary of Contents for RT362F

Page 2: ......

Page 3: ...General Information RANGES R RANGETOPS 1 1 SECTION 1 GENERAL INFORMATION ...

Page 13: ...Theory of Operation 2 1 RANGES R RANGETOPS SECTION 2 THEORY OF OPERATION ...

Page 20: ...RANGES R RANGETOPS Theory of Operation 2 8 ...

Page 21: ...Installation Information RANGES R RANGETOPS 3 1 SECTION 3 INSTALLATION INFORMATION ...

Page 26: ...RANGES R RANGETOPS Installation Information 3 6 ...

Page 27: ...Component Access Removal 4 1 RANGES R RANGETOPS SECTION 4 COMPONENT ACCESS AND REMOVAL ...

Page 43: ...Troubleshooting Guide 5 1 RANGES R RANGETOPS SECTION 5 TROUBLESHOOTING GUIDE ...

Page 53: ...Technical Data 6 1 RANGES R RANGETOPS SECTION 6 TECHNICAL DATA ...

Page 56: ...RANGES R RANGETOPS Technical Data 6 4 ...

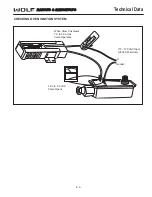

Page 57: ...R RA AN NG GE ES S R RA AN NG GE ET TO OP PS S Wiring Diagrams 7 1 WIRING DIAGRAMS SECTIO N 7 ...

Page 88: ...R RA AN NG GE ES S R RA AN NG GE ET TO OP PS S 7 32 Wiring Diagrams ...