Original operation manual

2K GEL UNIT

23

2KGel_14025_25015_BAoDB_en_1701 • rs

Transport, installation, and assembly

4.3.1 Installing the material hose and mixing unit

If the machine is delivered with WIWA material hoses and a WIWA mixing unit,

observe and follow the information in this chapter.

WARNING

Parts that are not designed for the maximum permissible working pressure

of the machine may rupture and cause serious injury.

➤

Prior to installation, check the maximum permissible working pressure of

the material hoses and the mixing unit. It must be greater than or equal

to the maximum working pressure of the machine stated on the type

plate.

WARNING

If the connections for the hoses are subjected to strain, these may be torn

out. The material escaping under high pressure may cause injuries and

damage to property.

➤

If tensile forces are anticipated on the hose connections (for example

due to the positioning of the mixing unit), it is necessary to utilize strain

relief!

1.

Close the material hoses at the material

outlet of the associated fluid pump.

Observe the color coding during the

component assignment.

A

B

Fig. 13: Connecting the material hoses

2.

Connect the material hoses to the

mixing unit.

Fig. 14: Connecting the mixing unit

B

A

3.

Install the coupling piece for the packer on the static mixer

of the mixing unit.

The selection of the coupling piece is

dependent on the type of packer used.

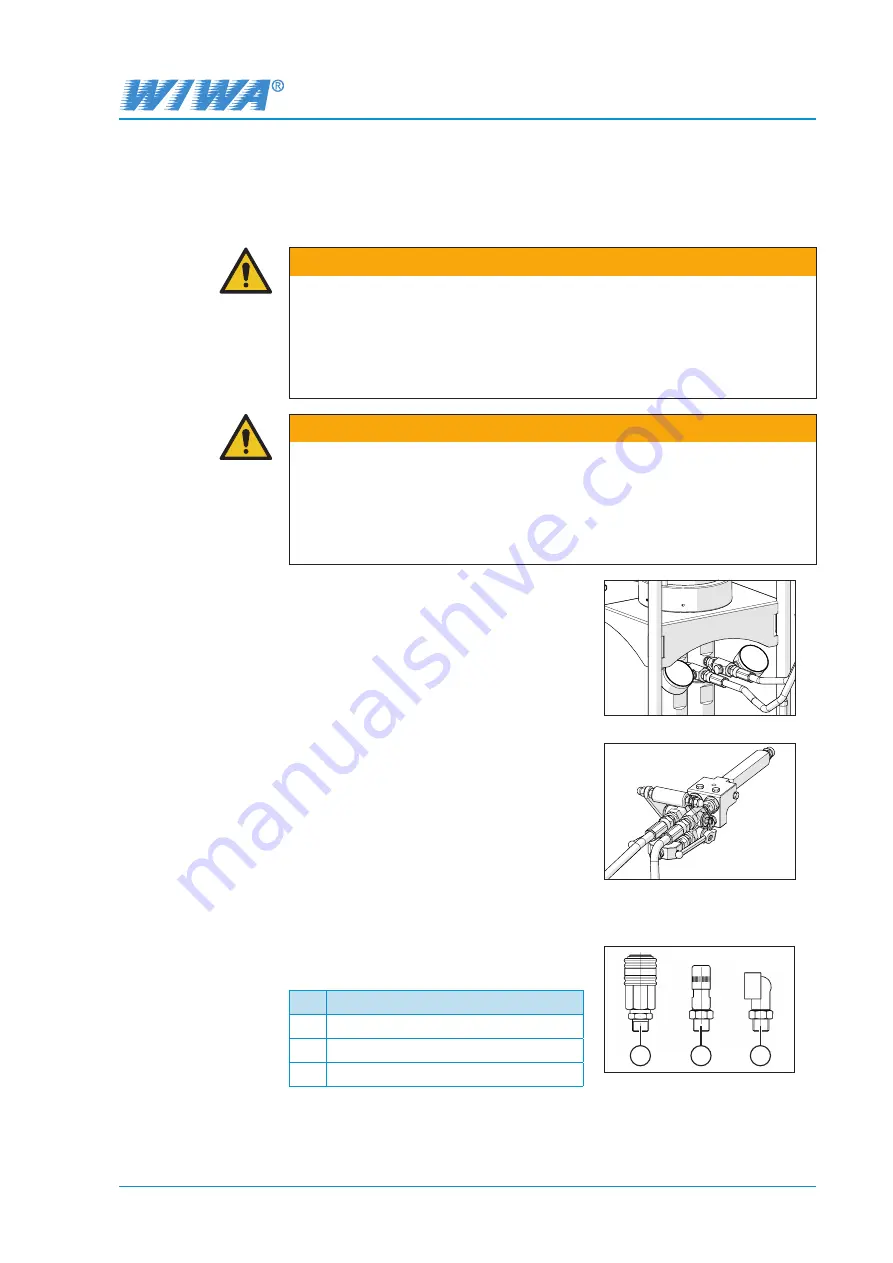

No. Coupling piece

1

Coupling G

¼

" I

2

Nozzle M10x1 IG

3

Slide coupling M10x1

Fig. 15: Coupling pieces for packer

1

2

3