Electrical installation

INTORQ | BA 14.0201 | 04/2016

20

5

Electrical installation

Important notes

5.1

Electrical connection

Ground/earth

Use the PE screw in the terminal box (Figures 6 and 8) to establish the PE (earth) connection.

PE connection via the fixing screws on the motor is not permitted because there is no electrically conductive

connection between the brake and the guide sleeves!

Temperature sensor connection (optional)

The spring-applied brake can be delivered with PTC sensors according to DIN 44082 for temperature mon-

itoring (reference temperature 130 °C). The signal is evaluated via a PTC thermistor tripping device provided

by the customer.

Connection: AWG 26 blue/blue

DANGER

There is a risk of injury by electrical shock!

❚

Electrical connection must only be carried out by skilled personnel!

❚

Only carry out connection work when no voltage is applied (no live parts)! There is a risk of

unintended start-ups or electric shock.

NOTICE

❚

It must be ensured that the supply voltage corresponds to the name plate data.

❚

Voltages must be adjusted to the local environment!

NOTICE

❚

If emergency switching off is carried out without the required suppressor circuit, the control

unit may be destroyed.

❚

Observe the correct polarity of the suppressor circuit!

Electrical installation

INTORQ | BA 14.0201 | 04/2016

21

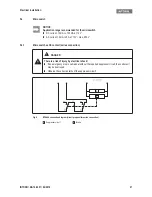

5.2

Microswitch

5.2.1

Microswitch as NC contact (series connection)

Fig. 5

BFK466 connection diagram (circuit proposal for series connection)

NOTICE

Application range recommended for the microswitch

❚

DC current: 10 mA to 100 mA at 12 V

❚

AC current: 10 mA to 5 A at 12 V / max. 250 V

DANGER

There is a risk of injury by electrical shock!

❚

If an emergency stop is carried out without the required suppressor circuit, the control unit

may be destroyed.

❚

Observe the correct polarity of the suppressor circuit!

AA

Suppressor circuit

B

Brake

A

B