V.. / NV.. / CV..

Maintenance and disposal

Revision: 05

2022-D059517

en-21

7

Maintenance and disposal

Read the general safety instructions before beginning to work (see Chapter 2.5 "General

safety instructions").

7.1

Maintenance schedule

7.2

Maintenance work

7.2.1 Visual inspection

Check the entire gearbox for exterior damage.

Seals are subject to wear. Therefore also check the gearbox for leakage during each visual

inspection.

Check the mounting position to ensure that no foreign medium (e.g. oil) has collected on

the output shaft.

The following only applies for

corrosion-resistant

gearboxes: Check the lacquer layer and

the nickel-plated surfaces for damages and corrosion.

7.2.2 Checking the tightening torques

Screw connections between gearbox and attached component such as motors have to be

calculated, dimensioned, mounted, and tested according to current technological standards. Use

the VDI directives VDI 2862 sheet 2 and VDI 2230 for example.

The tightening torques recommended by us can be found in Chapter 9 "Appendix".

Deviating from the recommendations in Chapter 5 "Assembly", washers may be used if the material

of the screw surface features a too low interface pressure.

The hardness of the washer needs to match the property class of the screw.

Take into account the washer for the screw calculation (joint, additional compression set,

surface pressure under screw head and under washer).

7.3

Startup after maintenance work

Clean the outside of the gearbox.

Attach all safety devices.

Do a trial run before releasing the gearbox again for operation.

7.4

Disposal

Consult our Customer Service department for supplementary information on disassembly and

disposal of the gearbox.

Dispose of the gearbox at the recycling sites intended for this purpose.

Observe the applicable national regulations concerning disposal.

Maintenance work

At startup

For the first time after 500

operating hours or 3 months

Every 3

months

Visual inspection

X

X

X

Checking the

tightening torques

X

Tbl-10: Maintenance schedule

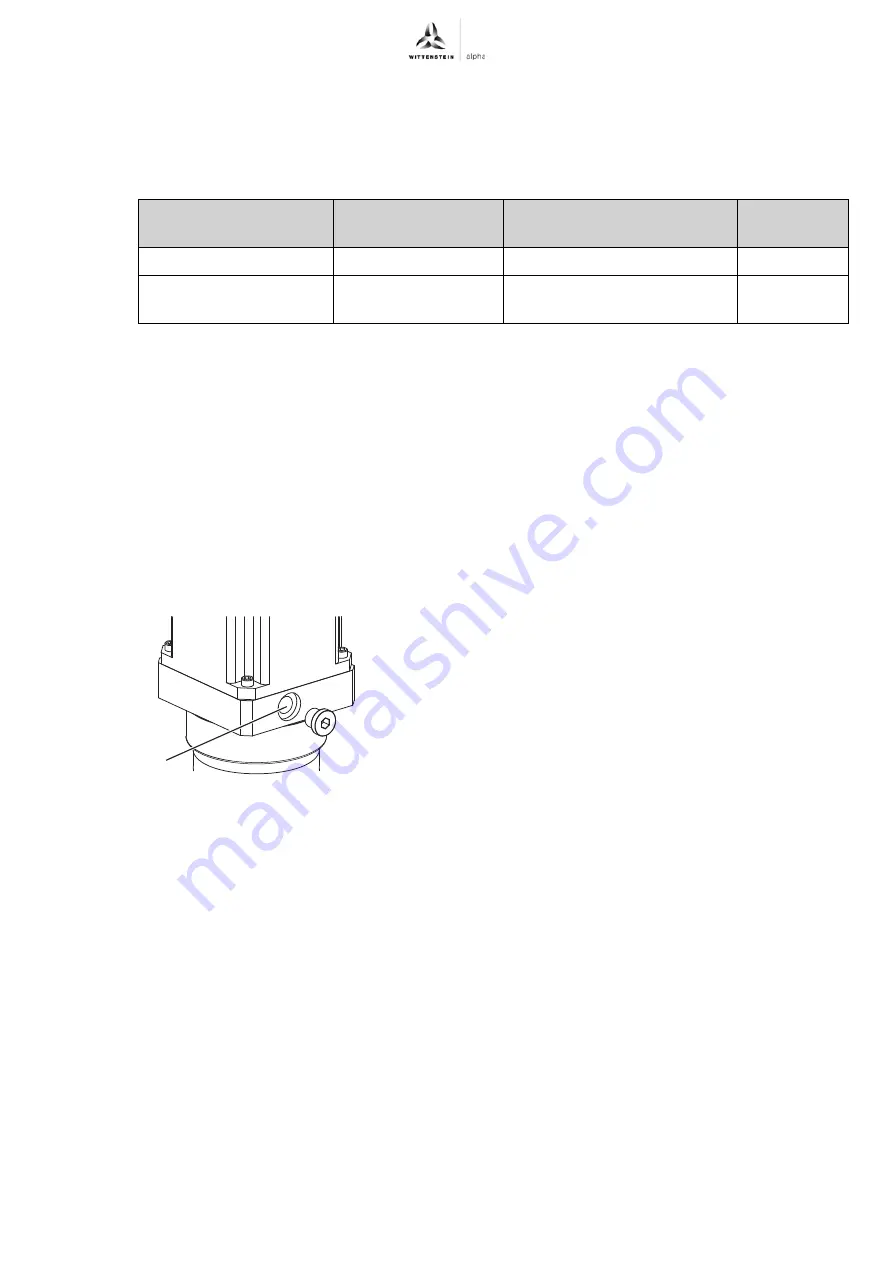

Check the tightening torque of the clamping bolt [H] on the

motor mounting. If, while checking the tightening torque, you

discover that the clamping bolt can be turned further, tighten it

to the prescribed tightening torque.

The value for the tightening torque can also be found in

Chapter 9.1 "Specifications for mounting to a motor".

H