Decals and Instruction Plates are attached to the equipment to warn against

hazards and assist in the safe operation of the equipment, if they become

damaged or defaced they must be replaced.

OPERATING INSTRUCTIONS FOUR WHEEL PAN

TROLLEY

The Four-Wheel Pan Trolley is designed to allow the safe and speedy removal

and transportation of the pan and mixed materials to wherever they may be

required within the plant. The following instructions should be followed to

ensure the Four Trolley is used safely and correctly.

1) It is recommended that the Trolley be used only on firm level ground.

2) On no account should the laden Trolley be left unattended on anything other

than a level surface unless the castors are securely chocked.

3) The area around the mixer should be kept free from any build up of waste

material.

4) Ensue the Pan Lifting Lugs and Hoop attached to the pan are in good

condition, secure and free from any build up of waste material.

5) Position the Trolley in front of the mixer so that the wheels are equally

spaced to each side of the mainframe/chassis.

6) Fully raise the Mixing Star by means of the handwheel and allow the pan to

come to a complete stop. Manually rotate the pan until two of the Pan Lifting

Lugs are at right angles to the mainframe/chassis. This will allow the Trolley,

when correctly positioned below the pan to cleanly lift the pan clear of the rack.

7) Push the Trolley under the pan until the ‘V’ support arms on the Trolley are

aligned below the Pan Lifting Lugs, brace the Trolley by placing a foot in the

rear centre of lower fixed frame and pull back on the handle until the ‘V’

supports are engaged with the Pan Lifting Lugs, continue pulling back on the

handle until it abuts the stops, at which point the pan will be clear of the rack.

Manoeuvre both pan and Trolley clear of the mixer. The Trolley complete with

the pan can now be carefully pushed or pulled to wherever the mixed material

is required. Be aware of the increased inertia inherent in the combined weight

of the Trolley, Pan and Material.

8) Before tipping the pan to discharge the material it is recommended that the

handle is moved fully forward to lower the upper moving frame of the Trolley

Summary of Contents for CUMFLOW RP50XD MK2

Page 4: ...OPERATING AND MAINTENANCE MANUAL SECTION 1 GENERAL INFORMATION RP50XD MK2...

Page 12: ...OPERATING AND MAINTENANCE MANUAL SECTION 2 INSTALLATION AND OPERATING INSTRUCTIONS...

Page 20: ...OPERATING AND MAINTENANCE MANUAL SECTION 3 TECHNICAL SPECIFICATION AND MAINTENANCE...

Page 27: ...LUBRICATION CHART...

Page 28: ...OPERATING AND MAINTENANCE MANUAL SECTION 4 MIXER SPARE PARTS...

Page 29: ...RP50XD MK2 MIXING PAN DRIVE...

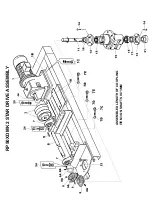

Page 32: ...RP50XD MK2 STAR DRIVE ASSEMBLY ASSEMBLED LENGTH OF COUPLING ITEM 3 ON SHAFTS IS 73MM...

Page 36: ...RP50XD MK2 MIXING STAR ASSEMBLY...

Page 38: ...RP50XD MK2 MIXING STAR LIFTING ARRANGEMENT...

Page 40: ...RP50XD MK2 COVERS GUARDS...

Page 43: ...PAGE INTENTIONALLY BLANK...

Page 47: ...RP50XD MK2 DECALS AND LOGOS CROKER CUMFLOW RP50XD 1 2 4 5 6 7 8 9 10 11 12 13...

Page 49: ...OPERATING AND MAINTENANCE MANUAL SECTION 5 ANCILLARY EQUIPMENT SPARE PARTS...

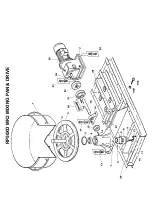

Page 50: ...RP50XD MK2 FOUR WHEEL PAN TROLLEY...

Page 53: ...OPERATING AND MAINTENANCE MANUAL SECTION 6 ELECTRICAL SYSTEM...

Page 55: ...Electrical Control Circuits dwg 11 03 02 10 55 09 Scaled to fit...

Page 56: ...V06302 dwg 11 12 02 07 03 44 Scaled to fit...

Page 57: ......

Page 58: ...Electrical Power Circuits dwg 11 03 02 10 58 17 Scaled to fit...

Page 59: ...V06303 dwg 11 12 02 07 04 45 Scaled to fit...

Page 60: ......

Page 61: ...General details of Control Panel dwg 11 03 02 11 01 09 Scaled to fit...

Page 62: ...V06301 dwg 11 12 02 07 02 37 Scaled to fit...

Page 63: ......

Page 64: ...Material Parts List dwg 11 03 02 11 03 32 Scaled to fit...

Page 65: ...V063PL1 dwg 11 12 02 07 01 06 Scaled to fit...

Page 66: ......

Page 67: ...OPERATING AND MAINTENANCE MANUAL SECTION 7 MISCELLANEOUS...