TH210-3 for MF

_____________________________________________________________________

_________________________________________________________

16

Configuring the Printer

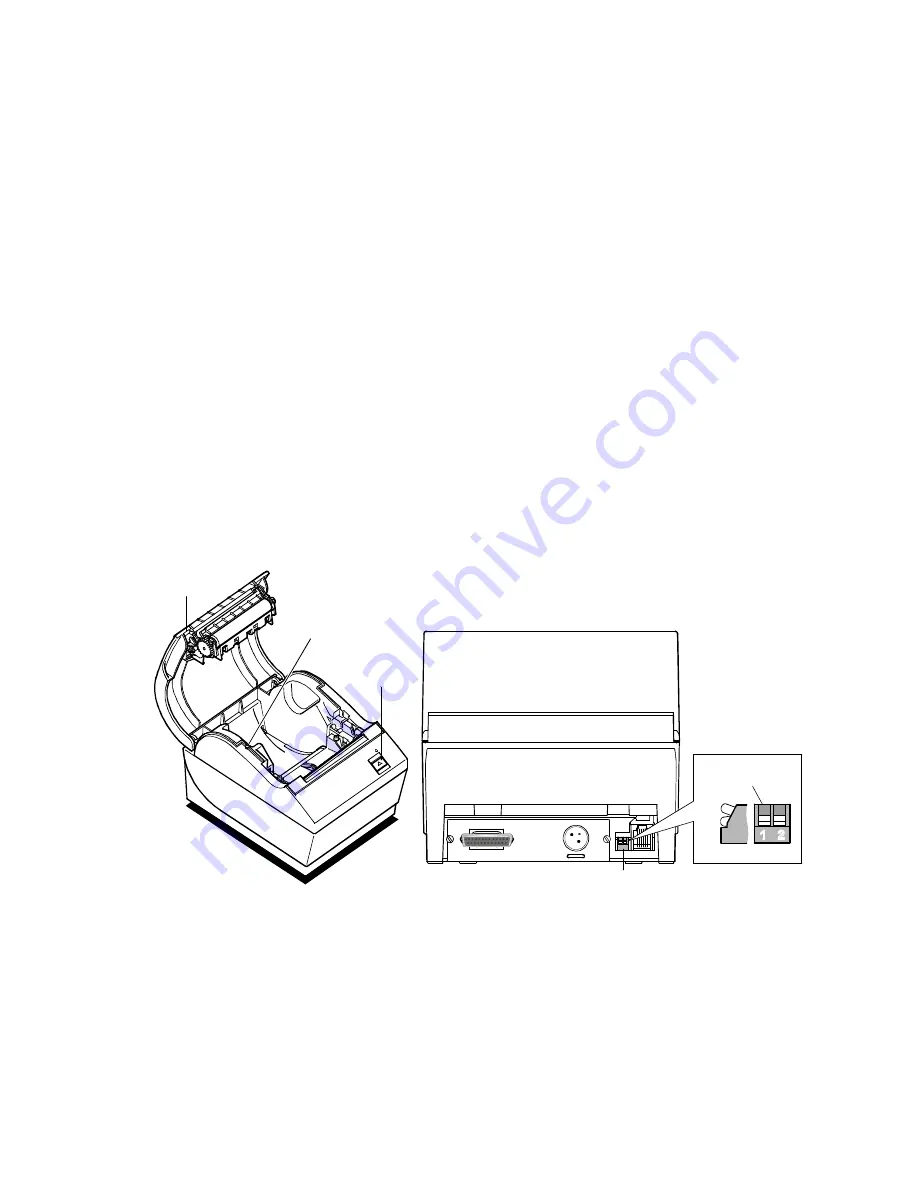

The Configuration Menu allows the user to set general printer

parameters. The test prints the settings for several functions, and

partially cuts the paper between each variation.

The printouts may vary for each model. The test ends with a partial cut

of the paper, then begins again. A test printout may use several feet of

paper to complete.

To start the test:

1. Set DIP Switch 1 to ON position (down.) DIP Switch 2 must

always

be set to ON position (down.)

2. Place paper into the bucket as described in the previous

section, “Changing Paper.”

3. Press the Reset Button.

4. Press and hold the Paper Feed Button while closing the cover.

P

a

p

e

r

F

e

e

d

B

u

t

t

o

n

R

e

s

e

t

B

u

t

t

o

n

O

f

f

S

w

i

t

c

h

1

i

s

s

h

o

w

n

i

n

t

h

e

O

N

p

o

s

i

t

i

o

n

O

n

D

I

P

S

w

i

t

c

h

e

s

1

2

B

a

c

k

o

f

P

r

i

n

t

e

r

D

I

P

S

w

i

t

c

h

e

s

R

e

a

r

C

o

v

e

r

Summary of Contents for TH210-3

Page 1: ...TH210 3 for MF Thermal Printer User Guide ...

Page 3: ...Published by Wincor Nixdorf International GmbH D 33094 Paderborn ...

Page 4: ...TH210 3 Thermal Printer User Guide Edition March 2010 for MF ...

Page 7: ...Paper Specifications 23 Print Zones 24 Print Zones for 80 mm Paper 24 List of Commands 25 ...