15

OPM-108/B

REFILLING COOLANT

1. Remove radiator cap.

Slowly

add coolant to the filler

opening.

2. Loosen the air bleeder plug of the EGR cooler to

remove any air from the coolant.

3. Tighten the air bleeder plug when the coolant

overflows.

4. Firmly close the radiator cap.

5. Fill the reserve tank up to the specified level, close the

reserve tank cap.

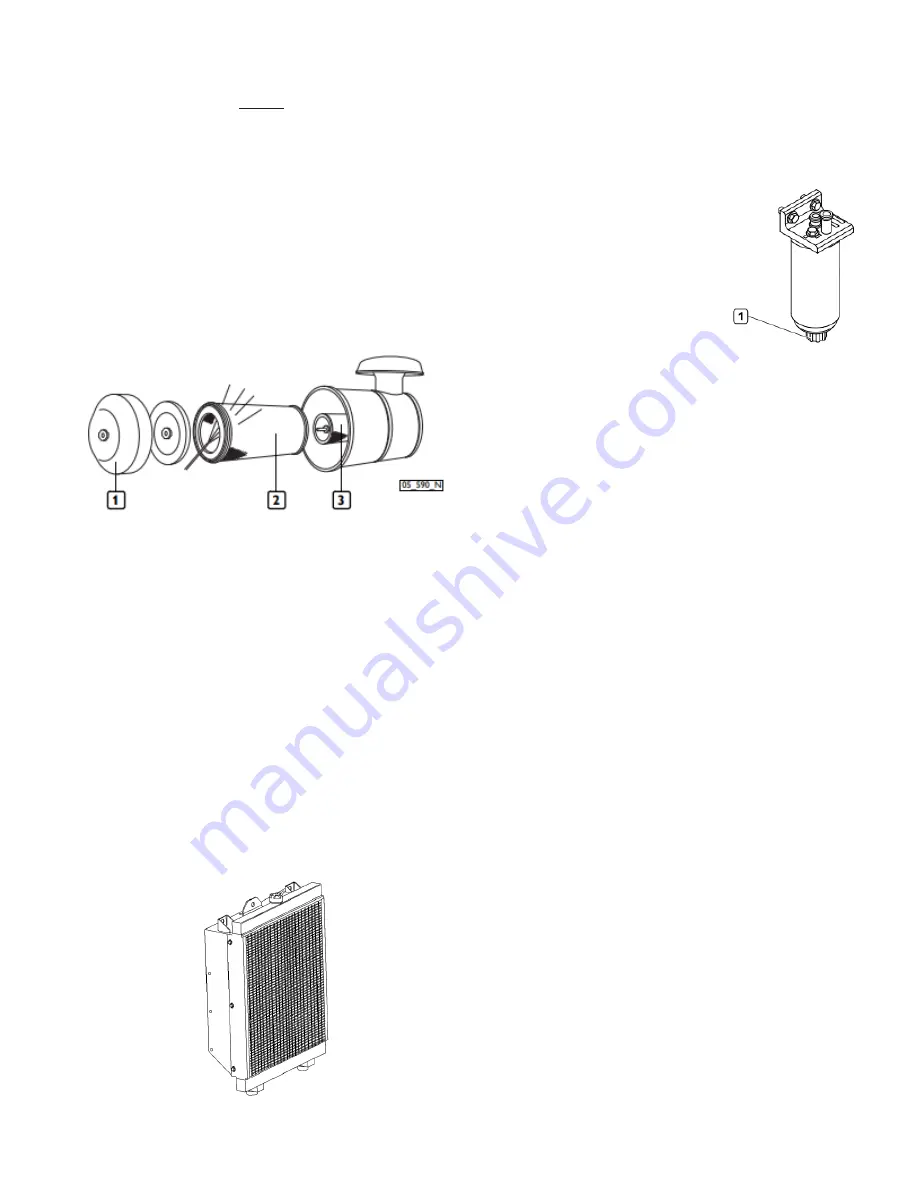

CHANGING AIR FILTER

Do NOT remove filter while engine is running.

1. Remove the air filter cover (1) after unscrewing the

locking

handle.

2. Remove the external cartridge (2), after unfastening

the second locking handle; during this operation, take

care to ensure that no dust get into the sleeve.

3. Replace the filter. Check that the gasket at its base is in

good

condition.

4. Reassemble by repeating the above operations in

reverse

order.

CLEANING RADIATOR

The surfaces of the radiator come into contact with the

outside air and can be subject to deposits and impurities.

Clean in accordance to the maintenance schedule with

compressed air or steam.

DRAINING WATER IN FUEL FILTER

WARNING: EQUIPMENT DAMAGE

Clean the exhaust valve prior to checking the pre-filter to

reduce the risk for system contamination.

Do NOT perform while the engine is running.

1. Place a container for collecting

liquids under the pre-filter.

2. Unscrew the plug located at the

bottom of the filter.

3. Drain the fluid until only fuel

comes out.

4. Fully hand-tighten the plug.

5. Dispose of liquid in accordance to local codes. DO NOT

dispose or allow liquid to seep into the ground or

sewer systems, doing so will cause environmental

damage.

CHANGING THE FUEL FILTER

1. Should the filter be fitted with a sensor to detect the

presence of water, remove the whole sensor from its

seat.

2. Remove the pre-filter by unscrewing it.

3. Check that the new filter has performance levels that

satisfy the needs of the engine (e.g. by comparing

them with the old one).

4. Damp the new filter seal with diesel or engine oil.

5. Hand screw the new filter into place until the seal

gasket touches the support, then lock by a further

3/4 of a turn.

6. (If equiped) Place the water presence sensor in

its seat, taking care to couple the threads correctly.

Loosen the bleeder screw on the pre-filter support

and activate the hand pump until the supply circuit is

full. Ensure that any fuel coming out is not dispersed

into the environment. Lock the bleeder screw tightly.

7. Start the engine and run it at minimum speed for a few

minutes to eliminate any residual air.

STORAGE

PREPARING THE ENGINE FOR A LONG PERIOD

OF INACTIVITY

In the case of a planned period of inactivity that lasts longer

than two months, to prevent the interior parts of the

engine and some components of the injection system from

oxidizing, prepare the engine as follows:

1. Drain the lubricant oil from the sump after heating the

engine.

2. Pour 30/M protective oil into the engine up to the