SCH & SCL

Oil Furnaces

–

Furnace Manual

24

670-000-006-1007

10

Service and maintenance

(continued)

Service/maintenance procedures

To inspect blower motor

Belt-drive motor – Blower bearings and the motor are permanently

lubricated and do not require oiling. Verify that the blower, motor

pulleys and belt are in good condition. Replace if necessary.

Direct-drive motor – Blower bearings and the motor are permanently

lubricated and do not require oiling.

Clean blower wheel – Vacuum dust from blower wheel blades and

surrounding area.

To clean heat exchanger

The heat exchanger must be cleaned and/or

inspected at least once each year. Operating the

furnace with a fouled or leaking heat exchanger

could result in severe personal injury, death or

substantial property damage.

The combustion chamber contains ceramic fiber

materials. Wear a NIOSH-approved respirator while

cleaning the furnace and follow WARNING on page

20 for proper handling.

1. Remove the burner.

2. Inspect the heat exchanger using a mirror inserted through the

burner opening.

3. Using a brush on a flexible handle, loosen the soot on the inside

of the heat exchanger.

4. Remove the soot with a vacuum. Be careful not to damage the

combustion chamber while cleaning the heat exchanger.

5. Open the heat exchanger cleanout cover, if present. Using a

brush on a flexible handle, loosen the soot from the heat

exchanger surfaces. Remove as much soot as possible using a

vacuum.

6. Close cleanout cover.

7. Inspect combustion chamber and replace with a new one if

chamber is damaged in any way.

8. Re-install

burner.

Obtain gas-tight seal at burner flange and cleanout

plates to prevent possible flue gas leakage and

carbon monoxide emissions, leading to severe

personal injury or death.

Inspect vent system

Thoroughly inspect the entire vent system at least annually. Ensure

vent system is repaired or replaced if necessary before placing

furnace in operation.

Oiled-bearing burner motors

The burner may need to be lubricated if motor is equipped with oiling

cups. Refer to burner manual for specific instructions. If instructed,

apply a few drops only of S.A.E. 20 detergent oil (never use

household oils). Do not attempt to “fill up” the oil cup. Over-oiling can

damage the motor.

Annual start up

Follow information below to prevent severe personal

injury, death or substantial property damage:

DANGER

•

Do not use gasoline, crankcase drainings or any oil

containing gasoline. See burner manual for proper

fuel oil.

•

Do not attempt to start burner when excess oil has

accumulated, when unit is full or vapor or when

combustion chamber is very hot.

•

Do not start burner unless vent and burner mounting

plate are secured in place.

•

Never burn garbage or paper in the furnace.

WARNING

•

Never leave combustible material around it.

To start furnace

WARNING

1. Factory burner adjustment and settings may not be suitable for

specific job conditions. Refer to burner manual as well as the

“Dimensions and Ratings” section of this manual for burner start

up, adjustment and checkout procedures.

2. Set room thermostat to call for heat.

3. Refer to burner manual for start up.

4. The furnace blower will delay for a short after burner starts, until

the limit/fan switch senses air temperature above the fan ON

setting.

5. Set room thermostat to its lowest setting. Burner should turn off.

6. Furnace blower will continue to run until the limit/fan switch

senses air temperature below the fan OFF setting.

7. Set the room thermostat to call for heat again. Allow furnace to

heat to design temperature. Then adjust burner for correct

combustion, using combustion test equipment. Adjust burner for:

CO

2

: between 10 % and 11 ½ %, with 0 smoke.

8. Take an overfire pressure reading (refer to Section 7)

Make final burner adjustments using combustion test

equipment to assure proper operation.

WARNING

WARNING

8. Check furnace and duct system for proper operation and

conditions.

9. Inspect vent system for proper operation.

10. To set limit/fan switch:

The blower operates until the air temperature drops below the

fan OFF setting. If the air at the supply registers is too warm at

blower start up or shutdown, lower the fan OFF and ON settings

on the limit/fan switch.

To check operation of the limit switch, slide a piece of cardboard

into the furnace filter slot. After a few minutes of operation (not

more than 5 minutes), the burner should shut off (limit switch

open). The blower will operate until the furnace cools down.

Remove cardboard when finished.

11. Complete testing of the burner cad cell control using the

instructions in the burner manual.

Summary of Contents for SCH High Boy

Page 12: ...SCH SCL Oil Furnaces Furnace Manual 12 670 000 006 1007...

Page 13: ...SCH SCL Oil Furnaces Furnace Manual 670 000 006 1007 13...

Page 14: ...SCH SCL Oil Furnaces Furnace Manual 14 670 000 006 1007...

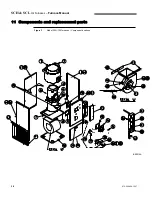

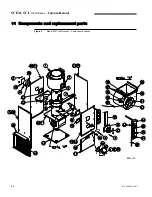

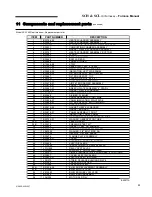

Page 25: ...SCH SCL Oil Furnaces Furnace Manual 670 000 006 1007 COMPONENTS AND REPLACEMENT PARTS 25...

Page 39: ...SCH SCL Oil Furnaces Furnace Manual 670 000 006 1007 X40132 Rev D 39...