2

670-000-006-1007

READ THIS FIRST!

Failure to adhere to the guidelines below can result in severe personal injury, death or substantial property damage.

WARNING

Service and maintenance

1.

To avoid electric shock, disconnect electrical supply before

performing maintenance.

2.

To avoid severe burns, allow furnace to cool before performing

maintenance.

3.

Perform service and maintenance as described in this manual

and the burner manual.

4.

Do not attempt to make adjustments to the blower or motor while

the furnace is in operation. Disconnect power to the furnace and

be sure all parts have stopped moving before attempting

adjustments or maintenance.

5.

The burner must be set up and adjusted using combustion test

instruments. Visual examination of the flame alone cannot

determine combustion performance.

Operation

6.

Do not use the furnace as a construction heater.

7.

Do not operate any furnace if the heat exchanger is damaged,

corroded or pitted. Toxic flue products could enter the air

stream.

8.

Do not jumper, attempt to by-pass or override any limit control.

9.

Do not block flow of combustion or ventilation air to furnace. Do

not block or obstruct the air openings in the furnace casing.

10.

Do not store or use combustible materials, gasoline, or other

flammable liquids or vapors in the furnace area.

11.

Do not operate the furnace if the furnace area will be exposed to

air contaminants.

12.

Should overheating occur, do not turn off or disconnect electrical

supply to furnace. Instead, shut off the oil supply at a location

external to the appliance, if possible.

13.

Do not use this furnace if any part has been under water.

Immediately call a qualified service technician to inspect the

furnace and to replace any part of the furnace, control system or

burner that has been under water.

14.

Do not operate furnace if temperature rise through heat

exchanger exceeds 85

o

F.

15.

Inspect, clean and replace (if necessary) return air filter

regularly.

16.

Do not obstruct return air grills or supply air outlets.

17.

Supply only #2 fuel oil to the burner. Never attempt to use

gasoline, a mixture of gasoline and oil, waste fuel, refuse or any

other substance in the burner of furnace.

Installation

18.

Do not block flow of combustion or ventilation air to furnace. Do

not block or obstruct the air openings in the furnace casing.

19.

Connect furnace only to a functional vent system in good

condition. Place the furnace so as to allow proper venting, with

the shortest possible venting and minimum number or elbows.

20.

Always connect and seal a return air duct to the furnace unless

the furnace is located in a large space, such as an unpartitioned

basement. Route the return air duct to an adjacent room if no

return air manifold is used.

21.

Install furnace maintaining minimum clearances for service and

separation from combustible surfaces described in this manual.

22.

Install, start-up, service and maintain burner per instructions in

this manual and the burner manual.

23.

Verify burner is properly inserted through the combustion

chamber opening.

24.

Furnace must be installed so that burner and control system

components are protected from dripping, spraying water or rain

during operation or service.

25.

If installing an air conditioning evaporator coil, install the coil

downstream of, or in parallel with, the furnace to prevent

condensation in the furnace heat exchanger. If the coil is in

parallel, provide means to prevent flow of chilled air into the

furnace, including an interlock to prevent simultaneous operation

of heating and air conditioning.

Apply the following suggestions to prevent unsatisfactory operation of the furnace.

NOTICE

Installation –

1.

Be sure to level the furnace, using a spirit level on the front and

one side. If the furnace is not level, oil can drip into the

combustion chamber after burner cycling, causing fouling of the

heat exchanger and the burner head.

2.

Make sure all legs are in contact with the floor to distribute the

load and prevent the possibility of undue noise or vibration.

3.

Avoid locating return grills in rooms that may contain undesirable

odors.

4.

Never locate a return air grill closer than approximately 20 feet

from the furnace.

5.

Locate the furnace near the center of the supply and return duct

systems.

6.

Always check the size of the ducts on a replacement installation,

particularly if adding air conditioning.

Summary of Contents for SCH High Boy

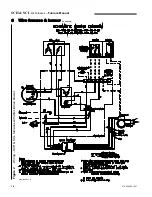

Page 12: ...SCH SCL Oil Furnaces Furnace Manual 12 670 000 006 1007...

Page 13: ...SCH SCL Oil Furnaces Furnace Manual 670 000 006 1007 13...

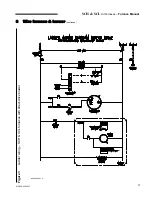

Page 14: ...SCH SCL Oil Furnaces Furnace Manual 14 670 000 006 1007...

Page 25: ...SCH SCL Oil Furnaces Furnace Manual 670 000 006 1007 COMPONENTS AND REPLACEMENT PARTS 25...

Page 39: ...SCH SCL Oil Furnaces Furnace Manual 670 000 006 1007 X40132 Rev D 39...