Page 14

15628-0-0903

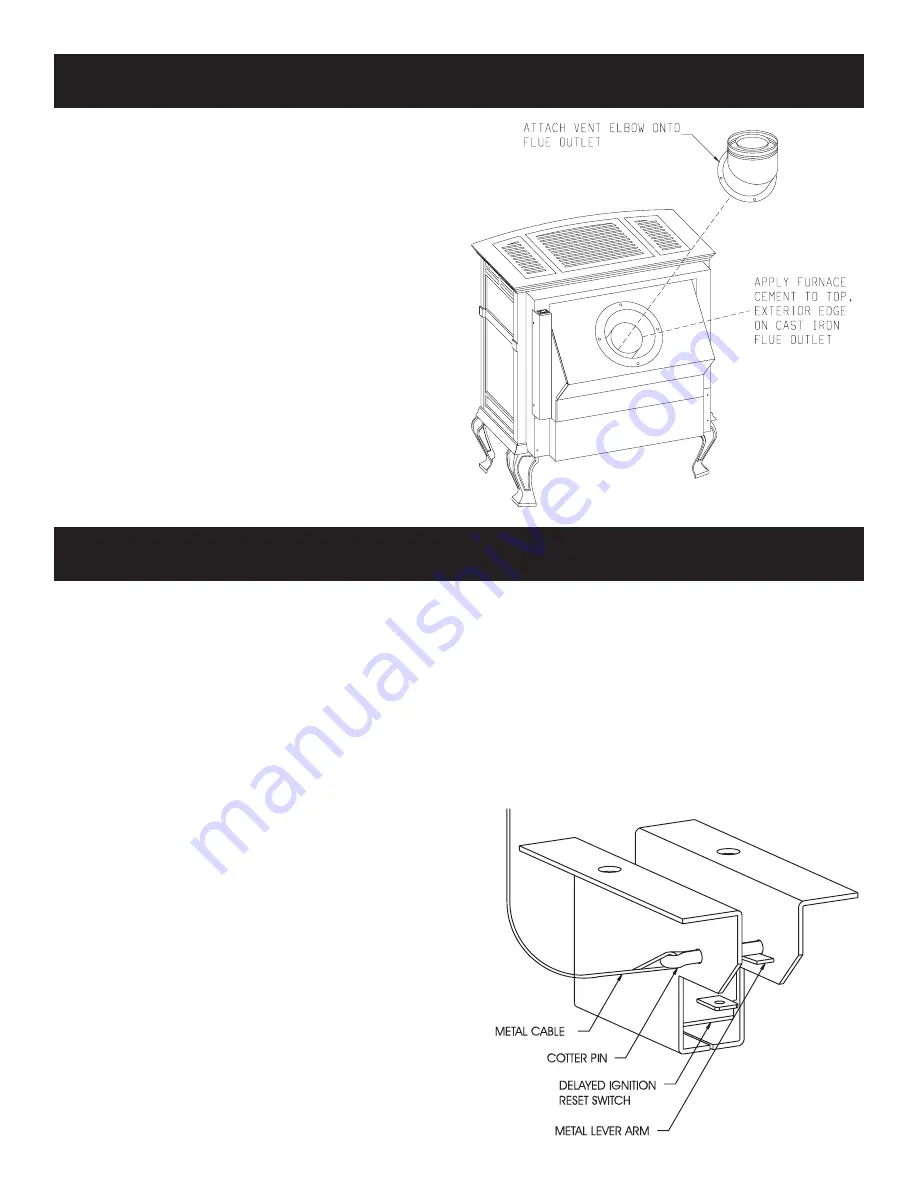

DELAYED IGNITION RESET SWITCH

Attach black wire from REMOTE/OFF/ON switch to the front

1/4" male tab on the reset switch. Attachment of black wire

onto the reset switch is done in conjunction with the preceding

steps for Wire Channel Installation. Attach black wire on the

back of the reset switch to the TH/TP terminal on gas valve.

The reset switch can be activated if the main burner has a delayed

ignition. The right, relief door is connected by a metal wire to a

cotter pin that is inserted into the reset switch. When a delayed

ignition occurs the right, relief door pivots upward, the metal wire

pulls the cotter pin out of the reset switch and the main burner is

shut OFF.

Whenever the delayed ignition reset switch is activated you

must contact a qualified service person to determine the cause

for the delayed ignition reset switch to be activated.

Replacement of cotter pin into delayed ignition reset switch

assembly by a qualified service person.

1. Lower valve cover.

2. The reset switch is located behind the right side of the valve

cover.

3. Verify the metal cable with attached cotter pin has free

movement.

4. Depress the metal lever arm located on the front of the reset

switch.

5. With the metal lever arm depressed, insert cotter pin into the

clearance hole on the right side of the bracket and into the

clearance hole on the left side of the bracket.

Attention: The tip of the cotter pin must remain flat. The

tip of the cotter pin must never be bent-over. If the tip of the

cotter pin is bent-over it could prevent the delayed ignition

reset switch from functioning during a delayed ignition.

6. Replacement of cotter pin into delayed ignition reset switch

assembly is completed.

Reassembly and Resealing Gas Accumulation Relief System

(Relief Doors) and Combustion Chamber

Whenever the relief doors are pivoted open by a delayed ignition

in the main burner, the relief door gaskets and combustion chamber

must be examined by a qualified service person for damage. All

damaged gaskets on the relief doors and combustion chamber

must be replaced by a qualified service person. If damage occurs

to the combustion chamber, it must be replaced by a qualified

service person. Contact Empire Comfort Systems, Inc. for

replacement parts.

Figure 15

Figure 14

DVKA-1 VENT ELBOW INSTALLATION

Attention: A tube of furnace cement is provided in the

Owner's Envelope. Apply furnace cement to the top, exterior

edge on the cast iron flue outlet.

Place the DVKA-1, vent elbow onto the flue outlet as you

align the clearance holes on the vent elbow with the clearance

holes on the vent elbow gasket.

Install the vent elbow onto the flue outlet with (4) hex-head

screws provided in hardware package. The vent elbow can

be installed in the vertical position or horizontal position.

All vent runs must have a minimum vertical rise of two

feet. If the vent elbow is installed in the horizontal position

and the vent run is directly behind the fireplace, you must

use Simpson Dura-Vent 36" snorkel, part number, SD-981

on exterior of the structure.