Page 10

15628-0-0903

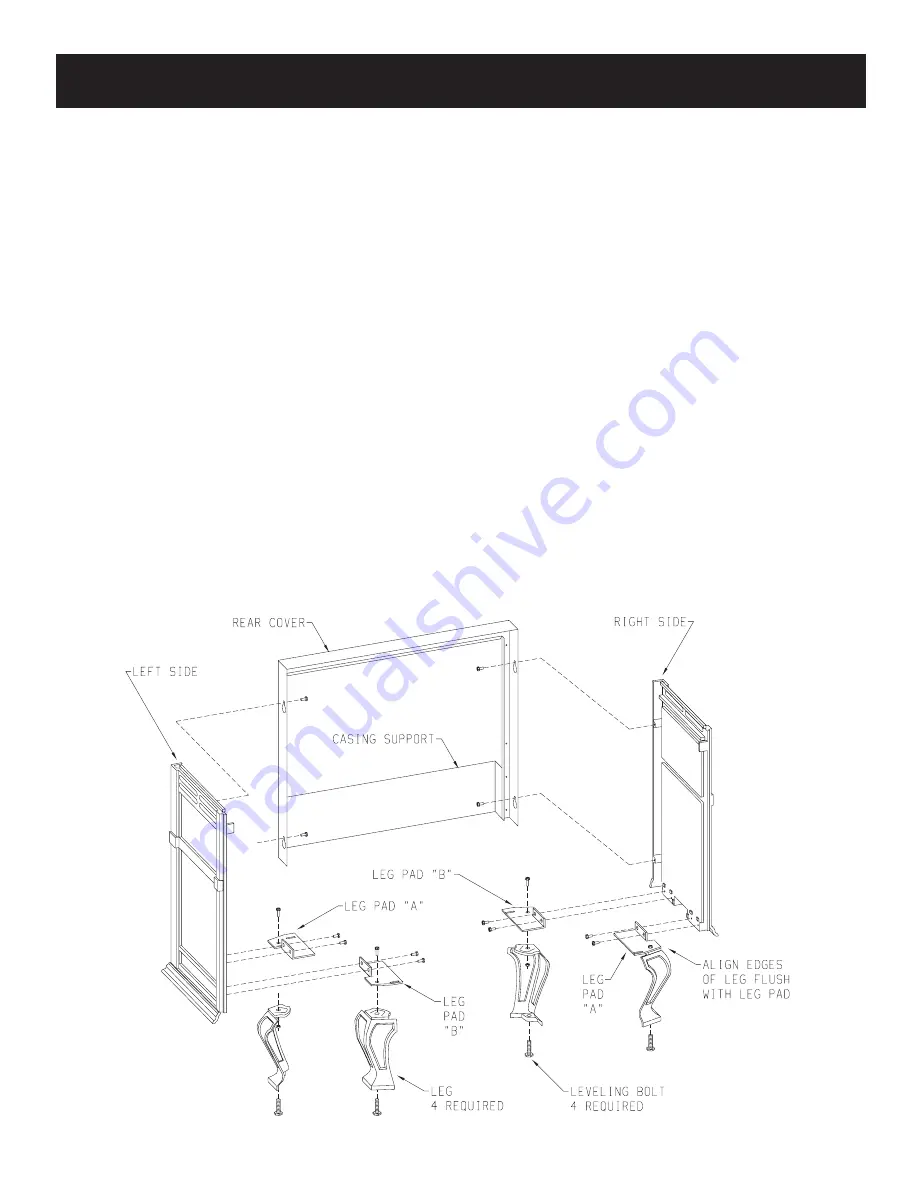

ASSEMBLY OF STOVE CASTING

Assembly of Stove Casting

(Figures 7, 8, 9, 10, 11, 12 and 13)

Attention: Included in the hardware package are (8) 1/4" inside

diameter washers. A 1/4" washer may be used with a 1/4-20 x

3/8" bolt when assembling the stove casting parts. If a bolt hole

is not tapped deep enough for a tight fit between stove casting

parts, the 1/4" washer can be used as a shim to provide a tight fit.

The 1/4" washers are not required for assembly of the stove

casting if all the bolt holes are tapped to a proper depth.

Additonal 1/4" washers are to be purchased locally.

1. Place porcelain casting pieces on a non-abrasive surface in

order to protect the porcelain finish. The exterior of the

porcelain casting pieces should be facing the non-abrasive

surface.

2. The assembly of the casting is accomplished in 7 stages:

A. Attaching legs to the sides (Figure 7).

B. Attaching rear cover to sides (Figure 8).

C. Removing protective packaging from casting front and

window (Figure 9).

D. Assembly of front by attaching retaining tabs and placing

front on unit (Figure 10).

E. Inserting firebox into partially completed assembly (Figure

11 and Figure 12).

F. Attaching firebox to rear cover (Figure 13).

G. Placing top on unit.

Detailed Instructions Follow

3. Refer to Figure 7, the leg pads will have the letter "A" and "B"

stamped into the metal. Place leg pad "A" and leg pad "B" at

the bottom of each casting side. Leg pad "A" attaches to the

front of the casting side, right and to the rear of the casting

side, left. Leg pad "B" attaches to the rear of the casting side,

right and to the front of the casting side, left. Position the 3/

4" flange on the leg pad against the (2) locator dimples on the

casting side. The 3/4" flange must be facing upward, toward

the top louver openings on the casting side. Attach the two

rear leg pads to the casting sides with (2) 3/8" bolts. Attach

but do not completely tighten the two front leg pads to the

casting sides with (2) 3/8" bolts. Attention: The front leg

pads can be adjusted to provide a snug fit between the casting

front and the casting sides.

4. Attach (4) leveling bolts to the bottom of the (4) legs.

5. Align the 3/8" hole at the top of the leg with the 3/8" hole in

the leg pad. Attention: For proper positioning of the leg to

the leg pad the (2) 1-1/2" top edges of the leg must be placed

flush and parallel to the (2) edges on the leg pad. Attach leg

to leg pad by inserting (1) 1" bolt through the leg pad and into

the leg, secure bolt with 1/4" nut.

6. Insert (2) 3/8" bolts into the (2) holes on the edges of the

casting sides. The bolts should only be threaded half-way

into the holes in order to allow for clearance when the casting

back is attached to the casting sides.

Figure 7