25

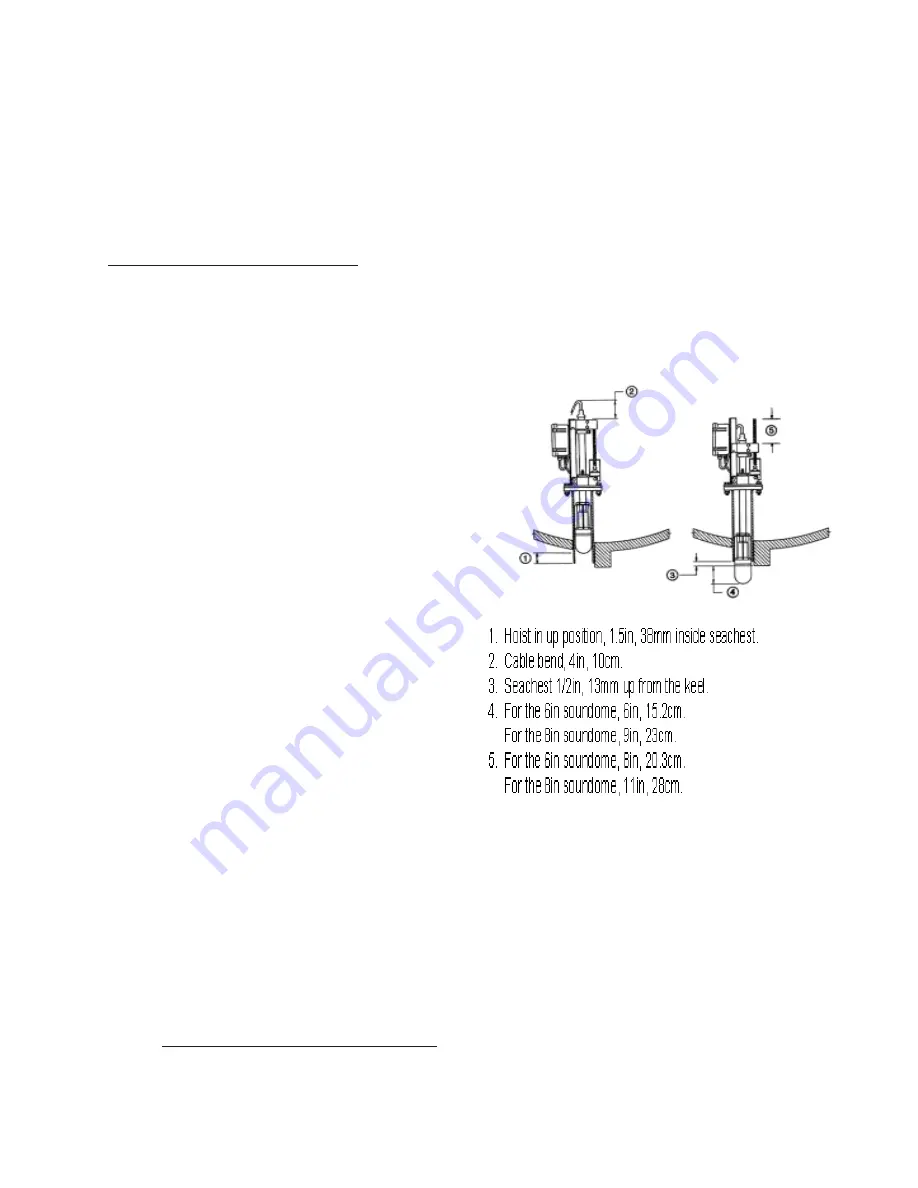

the distance the soundome travels beneath the keel,

item #4 below.

To make corrections loosen the top hoist clamp and

safety clamp. Move the soundome up or down for

the correct position.

2.5.3 Packing Gland

Tighten the packing gland by rotating the two nuts

hand tight then two complete turns

with a wrench Tighten the second nut agains the

first nut.

When the boat is back in the water, cycle the hoist

up and down four times. Check the packing gland

for water. It is normal for the packing gland to be

wet but not dripping with water. Retighten the

nuts on the packing gland.

WARNING:

Do not

tighten the packing gland too tight. A tight packing

gland will hold the soundome tube from moving,

either the fuse will blow or the bronze shear pin

will break.

2.6 Hydraulic Hoist

Installation

The hydraulic hoist will require some

assembly. There are four parts that make up the

complete hoist unit: hoist rack assembly, soundome

tube, hydraulic power pack with hydraulic ram and

soundome. There are two models of hydraulic pow-

er packs, DC and AC. The DC unit can be installed

on the hoist rack. The AC, due to its weight, must

be installed on a bulkhead. Bulkhead installation

may require some longer hydraulic lines.

NOTE: The soundome tube has been cut to

match the seachest on board. If there is any

uncertainty on the length contact your dealer

or WESMAR before proceeding with the in-

stallation

.

2.6.1 Assemble the soundome tube

1. Remove the packing gland cap and pack flax

Summary of Contents for SS395

Page 36: ...36...