TitanMig 200D Operators Manual

Issue. A 1216

Connect the gas hose to the regulator / flow meter located on the shield gas cylinder and connect the

other end to the machine.

Open the valve on the TIG torch slowly and set the flow rate for 12 l/min.

Select TIG function on the front panel.

“Scratch” the electrode on the work piece to start the arc.

(2)

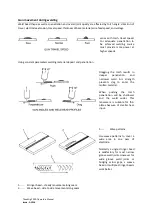

For the Tig Torch with Europe connection.

Connect the TIG torch to the Euro connection on the front of the machine and tighten it.

Insert the earth cable plug into the Positive socket on the front of the machine and tighten it.

Insert the weld power cable plug into the Negative socket on the front of the machine and tighten it.

Connect the gas line of the TIG torch to regulator and connect the regulator to the gas cylinder.

Connect the gas line to the machine via the quick push lock connector located on the rear panel.

Open the gas valve cylinder slowly and set the flow rate for 12 l/min.

Select TIG function on the front panel.

4.0

Trouble Shooting

4.1 Mig Welding Trouble Shooting

The following chart addresses some common problems during MIG Welding.

In the event of equipment malfunction, contact an authorized service agent.

Possible Reason

Suggested Solution

The Welding current is unstable

The pressure arm on the wire feeder is not

properly adjusted

Adjust it to get proper pressure.

The drive roll does not match the wire size being

used.

Make sure they match with each other.

The contact tip of the welding torch is badly

worn.

Replace it.

The wire-feeding tube of the welding torch is

badly worn.

Replace it

The welding wire is of poor quality

Replace it with welding wire of good quality

Excessive Spatter

Wire feed speed set too high

Select lower wire speed

Voltage to high

Select a lower voltage setting

Wrong polarity Set

Select the correct polarity for the wire being used

Stick out too long

Bring the torch closer to the work piece

Contaminated base metal

Remove any paint , grease, oil & dirt

Contaminated MIG Wire

Use clear dry rust free wire only.

Gas Flow too high or too low

Check gas is connected. Set gas flow between 10-15 l/min. Protect Weld Zone

from wind & drafts

Porosity

Wrong Gas

Check that correct gas is being used