TitanMig 200D Operators Manual

Issue. A 1216

Carbon Dioxide is less than ideal for use alone as a shielding gas but it is an essential ingredient of

most GMAW shielding mixtures.

High Carbon Dioxide (18 to 23%) mixtures are particularly suited to welding steels which are coated

with paint, primers and other surface contaminants, or where higher penetration is required.

Helium

Rarely used alone as a shielding gas.

Completely inert.

Lighter than air therefore less efficient as a shield.

High ionization potential which can cause arc initiation problems.

Essential ingredient for many shielding gas mixtures.

Helium rich shielding gas mixtures provide excellent weld fusion characteristics for GMA welding

applications. The high heat input obtained by using helium produces a hot arc and allows for high

deposition welding.

Oxygen

Oxygen is never used as a shielding gas on its own.

Oxygen is a vital component in many mixtures and performs two main functions…

It aids stability within the arc ionizing at a similar level to argon and influences the arc rooting

characteristics by producing a uniform oxide layer on the electrode and work piece.

It also reduces the surface tension of the metal droplets and the molten weld pool.

The benefits of these two functions are reduced wire losses as a result of spatter and the more

efficient use of deposited metal due to reduced reinforcement (weld metal build-up).

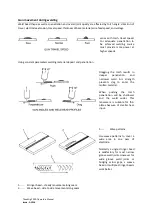

Penetration Profiles

Different shielding gas formulations produce quite different and significant changes to the

penetration

profile

of the weld.

Selecting the Correct Shielding Gas

Base Material considerations

Base material type or classification

Base material thickness

Joint design

Welding position

Metal transfer mode

Spray transfer

Globular transfer

Dip transfer

Pulsed current transfer

Quality aspect of the finished weld

Mechanical and chemical requirement

Surface finish

Penetration

Economics of the weld

Clean up costs (acceptable level of spatter)

Welding travel speed

Flow rate of shielding gas

Cost of shielding gas

Carbon Steel - Low content CO2 Mixtures

Most shielding gases are based on the argon/carbon dioxide/oxygen system for welding carbon steels.

Low content CO2 mixture (1-7% CO2) produce welds with a “Wine Glass” penetration profile similar to

that produced by pure argon, along with a very stable arc and low spatter levels.