TitanMig 200D Operators Manual

Issue. A 1216

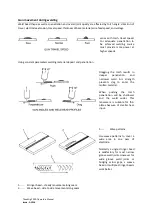

3.2 MMAW (Stick/MMA) Welding

Insert the cable plug with electrode holder into

the “+” socket on the front panel of the welding

machine, and tighten it clockwise.

Insert the cable plug of the work return lead into

the “-” socket on the front panel of the welding

machine, and tighten it clockwise

After connecting the welding leads as detailed you

will need to switch the power switch on the back

panel to “ON”

Select MMA by switching to the MMA welding

mode. There is voltage output at both output

terminals.

Set the amperage on the machine suitable for the

electrode being used. Ensure you check that you

have the electrode polarity correct.

Please see below a guide to amperages required.

Electrode Diameter(mm)

Welding Current(A)

Electrode Diameter(mm)

Welding Current(A)

2.0

40-60

4.0

130-180

2.5

60-95

5.0

180-220

3.2

95-130

6.0

220-260

Average Thickness of

Material (mm)

Suggested Electrode

Diameter (mm)

Average Thickness of

Material (mm)

Suggested Electrode

Diameter (mm)

1.0-2.0

2.5

5.0-8.0

4.0

2.0-5.0

3.2

8.0 >

5.0

TIG Welding

(1)

For the TIG torch with Dinse connection

Insert the cable plug with the work clamp into the “+” socket on the front panel of the welding machine,

and tighten it clockwise.

Insert the cables plug of the TIG torch into the “-” socket on the front panel of the machine or insert the

Europe plug of the TIG torch into the Europe socket(for the torch with Europe connector) and tighten

clockwise.