TitanMig 200D Operators Manual

Issue. A 1216

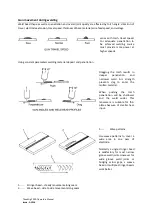

Installation of wire reel

Open the side cover and unscrew reel brake cover. Mount the reel in such way that one

end of wire hangs downwards. Mount brake cover back in position.

Cut off the bent end of the wire. Lead the end of the wire trough inlet guide and unclip

pressure handle of feed rollers in order to make the work easier. Ensure both wire inlet

guide and the feeding rollers groove are aligned. Push the welding wire to the inlet of the

torch connection. Replace the pressure handle to re-establish pressure on the wire. If

handle pressure is too strong the wire could be transformed - flattened. If the pressure is

too low the wire could slip in the feeding groove. Use tension knob to adjust this.

Gas selection for Gas Metal Arc Welding (GMAW)

Metal inert gas welding (MIG): Uses Argon (Ar), Helium (He) or Ar-He mixtures as the shield gas, and it

mainly used for welding aluminum and its alloys.

Metal active gas welding (MAG): Uses Argon (Ar) mixed with a certain amount of CO2 / O2 as the shield

gas, and it usually used in short circuit transfer and spray transfer. It can be applicable to flat position

welding, vertical position welding, overhead position welding and all-position welding, and it mainly used

for welding carbon steel, high strength low alloy steel and stainless steel. Welding robots mostly use the

MAG process.

CO2 (carbon dioxide) gas shielded arc welding (CO2 welding): It uses CO2 as the shield gas, and is usually

used in globular transfer and short circuit transfer to implement welding. It can be used to weld in

different positions. As compared with other welding methods, CO2 welding has many advantages, though

it produces more spatters, CO2 welding is widely used for general metal structure welding.

The correct shielding gas can alter productivity in GMAW by contributing to.

Correct weld sizes, to reduce over welding

Lower spatter levels, to increase welding speed and reduce clean-up

Reduced welding defects which reduces rework time

Reduced fume levels, to improve OH&S and worker comfort, increases productivity

Shielding gases have a strong influence over..

Stability of the arc

The shape of the weld bead/face

Mechanical properties of the weld

Cost efficiency of the welding process being used

Control of fume generation rates

Gases used in Shielding Gas Formulations

Argon

The tendency for argon to produce a “Wine Glass” penetration profile can make it difficult to ensure

complete fusion of the weld especially if “Arc Wander” is occurring.

For GMAW applications small additions of oxygen or carbon dioxide will assist in eliminating “Arc

Wander” by producing a uniformly oxidized surface for the arc root to “Anchor” to. The addition of

helium produces a broader and deeper fusion profile.

Carbon Dioxide CO2

The first shielding gas used for GMAW, MIG welding.

Spray transfer using GMAW cannot be achieved with carbon dioxide.

At low currents a good dip transfer mode can be obtained.

At high currents the transfer mode is globular and significant spatter is produced