User Manual

12

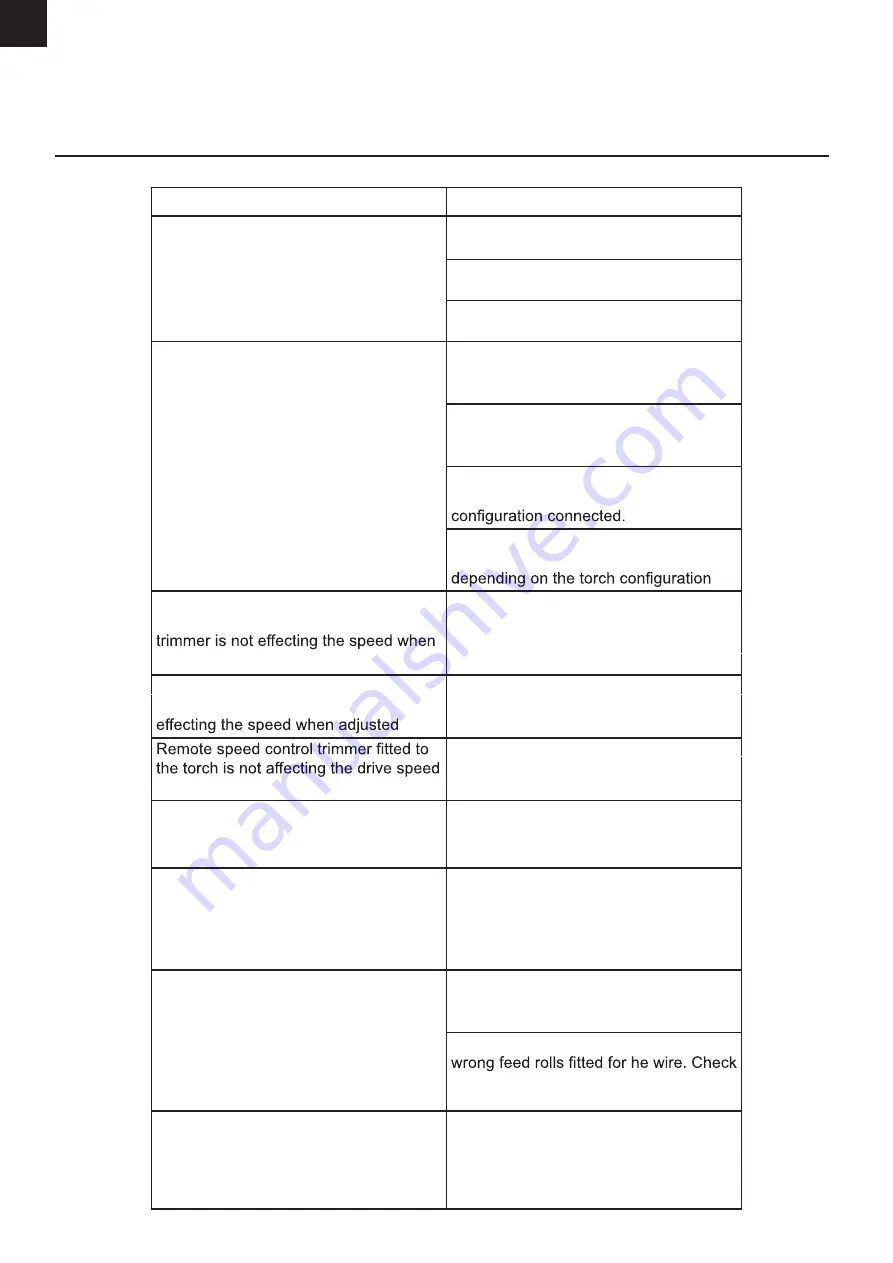

Trouble Shooting

Wire feeding erratic

Roll pressure is too low, adjust the

pressure by tightening the adjustment

knob on the side of the torch.

Torch feed rolls may be worn or the

the feed roll condition and replace if

necessary.

Torch drive roll rotates counter-

clockwise, against the direction of wire

feeding.

Drive motor power supply is connected

in reverse polarity. Open the torch

gun plug housing and swap the wire

connections for the drive motor. The

“Red” and “Black” leads.

Problem

Remedy

Wire feeder does not activate when

torch trigger is operated

Check and secure torch gun plug

connection with the feeding machine

Check torch trigger is operating and

connection is made through the torch

Check feeding machine via the users

manual

Wire feeder activates when torch trigger

is operated but torch drive does not

feed

Check and secure the control lead

connection with the drive module

Check the input voltage and drive signal

lead connection are made to the correct

terminals in the source feeder machine.

Check the speed control selector switch

is in the correct position for the torch

Adjust the speed control trimmer,

either on the drive module or the torch

Torch drive speed running at maximum

when the trigger is operated, speed

adjusted

Torch control lead wires may be

connected incorrectly.

Torch drive is not running when the

trigger is operated, speed trimmer is not

Torch control lead wires may be

connected incorrectly.

when adjusted

Check the connections as secure

through the torch and with the control

lead to the drive module

Wire “birds nests” in torch feed unit

behind the feed rolls

Pull drive speed is too slow. Adjust the

speed using the local or remote controls

depending on torch set up.

Excessive debris build up in torch drive

unit

Pull drive speed is too fast, slipping

on the wire and abrading the wire

surface. Adjust the pull feed speed

using the local or remote speed controls

depending on torch set up.