7

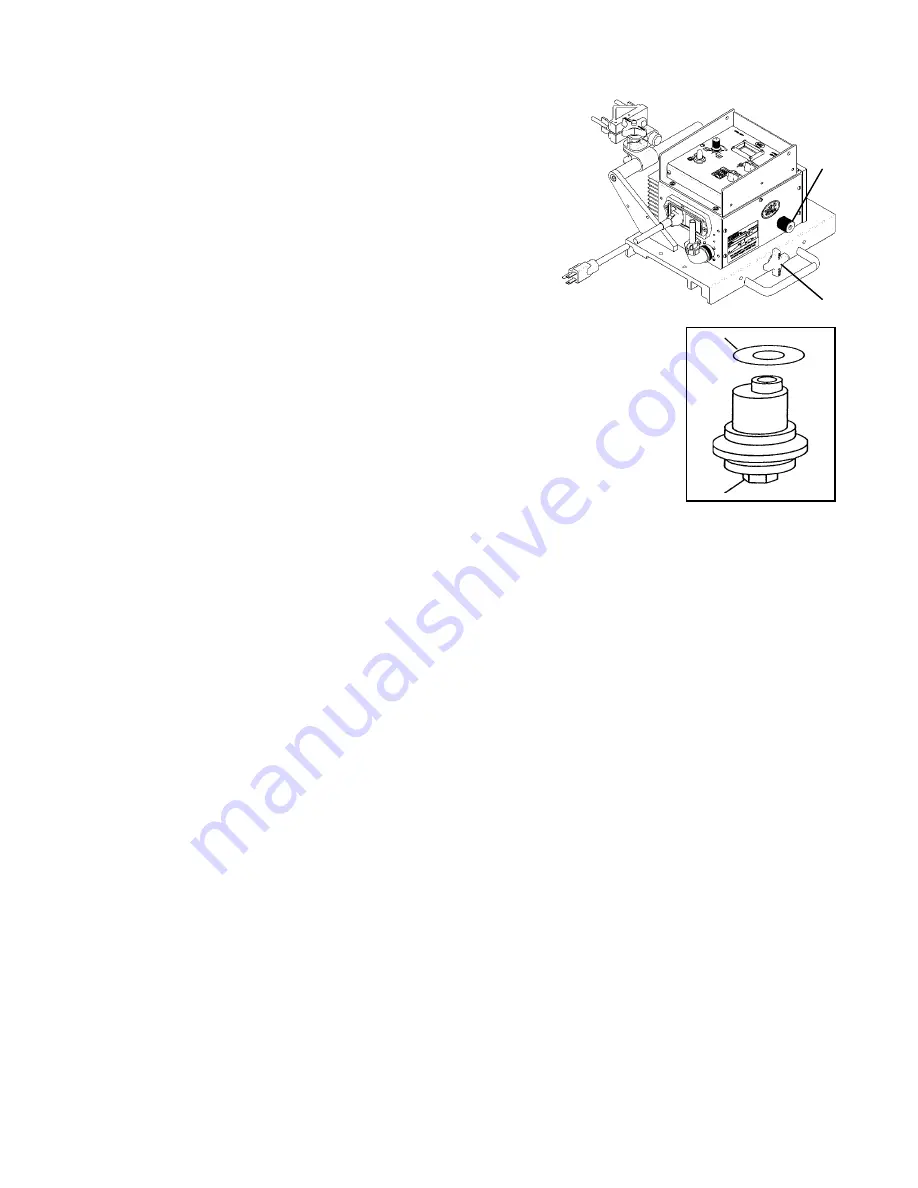

1) WHEEL ADJUSTMENT AND ALIGNMENT

Always check for proper carriage wheel adjustment before

using the machine. Turn the wheel engagement knob

(A)

on the side of the carriage until the wheels are fully moved

towards the center of the carriage (engaged). Then rotate

the master drive clutch knob

(B)

fully counter clockwise to

disengage the drive pinion. Slide the carriage onto the end of

a track. The wheels should slide into the track V-grooves and

the carriage will move smoothly along the track if the wheels

are properly aligned.

The wheels along one side of the carriage have stainless steel shim wash

-

ers

(C)

underneath. These wheels are adjustable. Readjust these wheels (if

necessary) by rotating the hex bolt

(D)

with a 1/2" wrench.

Grasp the sides of the carriage. The wheels are too loose if it is possible to

move the carriage from side to side or up and down. Use a finger to keep one

of the adjustable wheels from rotating as the carriage is manually pushed

along the track. The wheels are adjusted too tight if firm finger pressure is not

enough to prevent wheel rotation. Repeat the process for the other adjustable

wheel.

2) POSITIONING THE MACHINE ON THE TRACK

Position the rail using magnet plates or vacuum cups. Wipe the track grooves free of weld splatter and other

debris. This will prevent binding and premature rail and wheel wear. Lubricate the rack using a dry spray, if

desired, for extended track life.

Turn the wheel engagement knob

(A)

on the side of the carriage fully counter clockwise to disengage the

wheels. Then rotate the Master Drive clutch knob

(B)

fully counter clockwise to disengage the drive pinion.

The carriage can now be placed anywhere on the track. Turn the wheel engagement knob

(A)

clockwise

to engage the wheels firmly in the V-grooves. Verify all four wheels are in the grooves. Manually move the

carriage along the track to verify the motion is smooth and the wheel alignment is correct. Rotate the Master

Drive clutch knob

(B)

fully clockwise while gently rocking the machine forward and backward to fully engage

the drive pinion. The rocking motion is necessary to help insure proper gear mesh.

SETUP

C

D

B

A

3) REMOTE CONTACTOR WIRING

Connect the remote weld contactor on the main drive unit to the welding source as shown below:

Pins A and B ................. connection for Output #1

Pins C and D ................ connection for Output #2

5) MACHINE OPERATION

Turn the main power ON at the power entry box. Set parameters on control module in use.

4) GUN AND TORCH SETUP

For welding, insert the welding gun into the all-position clamp on the rack. Adjust the clamp, the clamp block

and the rack to position the gun for welding. Connect the weld contactor connector to the rear of the main

drive unit. Route the welding cable and weld contactor wires through the cable anchor clamp.

For cutting, insert the cutting torch into the torchholder on the rack. Adjust the torchholder, the clamp block

and the rack to position the torch for cutting. Connect the hose assembly to the manifold and the cutting

torch. The manifold acts as a strain relief on the supply hoses as well as a quick shut-off valve for the gases.

Once the torch valves are adjusted, the manifold eliminates the need for continuous adjustments and keeps

the supply lines from dragging the torch out of position.