22

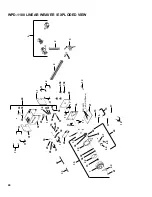

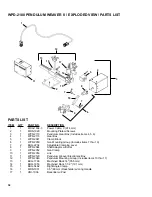

WPD-1100 LINEAR WEAVER

The

Linear Weaver

and

Weaver Control Module

add weave welding capability to the Modular Drive System.

The Linear Weaver bolts onto the front of the carriage and the Weaver Control Module plugs into the top of the

Master Drive Unit. The optional MDS-1060 Remote Control Cable can be used to remote the Control Module.

FEATURES

The Linear Weaver and Weaver Control Module incorporate the following standard features:

•

High torque, low inertia motor for precise stops and starts.

•

High speed Linear Weaver for weaving, with independent control of right and left dwell times.

•

High motor gearing which prevents the crossarm from moving when the unit is turned off.

•

Closed loop speed control for adjustable and repeatable control of critical welding or cutting parameters.

•

Closed loop position control to prevent drift from the center weld position.

•

Clutch, to enable rapid installation or replacement of the weaver cross arm.

•

Gun mounting group with adjustable racking block for accurate positioning of the gun.

•

Contactor ON/OFF switch.

The figure below shows how the Linear Weaver and Weaver Control Module connect to the carriage and

Master Drive Unit.

INTRODUCTION

LINEAR WEAVER

CROSS ARM

LINEAR WEAVER

WEAVER

CONTROL

MODULE

CARRIAGE

MASTER DRIVE UNIT

WEAVER CLUTCH

(KNOB ADJUSTMENT)

GUN MOUNTING

GROUP