25

LINEAR WEAVER SETUP, CONT’D.

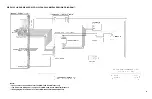

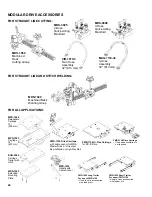

4) REMOTE CONTACTOR WIRING

Connect the remote weld contactor on the Master Drive to the welding source as shown below.

Pins A and B

...................connection for Output #1

Pins C and D

...................connection for Output #2

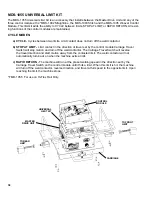

5) GUN AND SETUP

For welding, insert the welding gun into the all-position clamp on the rack. Adjust the clamp, the clamp

block and the rack to position the gun for welding. Connect the weld contactor connector to the rear of the

Master Drive Unit. Route the welding cable and weld contactor wires through the cable anchor clamp. Turn

on the AC power. Use the steering knob on the control module to move the crossarm to both the extreme

left and then the extreme right. Turn on the oscillator, at the same time, with the controls set to maximum

weave width. Readjust the crossarm or the gun if the racking fixture hits the case during operation.

6) MACHINE OPERATION

Turn the main power ON at the power entry box. Set the following parameters using the MDS-1005

Control Module (Ref. pg. 18 for illustration):

Weld Mode Selector Switch

Tractor Speed Control

Steering Control

Weave Amplitude

Weave Speed

Left and Right Dwells

The Start/Stop control will turn on the weaver. To start welding, push the weld contactor switch “ON” (mo

-

mentarily) which will turn on the wire feeder/weld current. Use the carriage travel switch to select a forward

or reverse carriage travel direction.

CAUTION:

The Speed Control Card in the Linear Weaver is

NOT

interchangeable with the speed card in

the Master Drive or Pendulum Weaver.