6

Certifi cations/approvals

Underwriters Laboratories has certi

fi

ed this burner

to comply with ANSI/UL 296 and CSA-B139.

Low

sulfur #1 and #2 fuel oils reduce heat exchanger

deposits with all burners compared to the standard

fuels. Reduced deposits extend the service

interval for cleaning and improve the effi ciency of

the appliance over time. Low sulfur fuels reduce

particulate and oxides of nitrogen emissions as

well. The Oilheat Manufacturers’ Association

recommends these fuels as the preferred fuels for

this burner.

Notice Special Requirements

THE INSTALLATION OF A BURNER SHALL BE IN

ACCORDANCE WITH THE REGULATIONS OF

AUTHORITIES HAVING JURISDICTION.

For recommended installation practices in the U.S.

refer to the latest edition of NFPA 31. (CSA-B139

and CSA-B140 in Canada.

Concealed damage — If you discover damage to

the burner or controls during unpacking, notify the

carrier at once and

fi

le the appropriate claim.

When contacting Beckett for service information

— Please record the burner serial number (and have

available when calling or writing). You will

fi

nd the

serial number on the silver label located on the left

rear of the burner. Refer to Figure 1.

○

○

○

○

Starting with minimum gph

fi

ring rate, the minimum

size recommended is 6”

fl

ue pipe with 8” X 8”

inside chimney, unless speci

fi

ed otherwise by the

appliance manufacturer.

A chimney

fl

ue shall extend at least 3 feet above

the highest point at which the chimney comes in

contact with the roof, and not less than 2 feet above

the highest roof surface or structure within 10 feet

horizontally of the chimney. Refer to Figure 2.

1.

2.

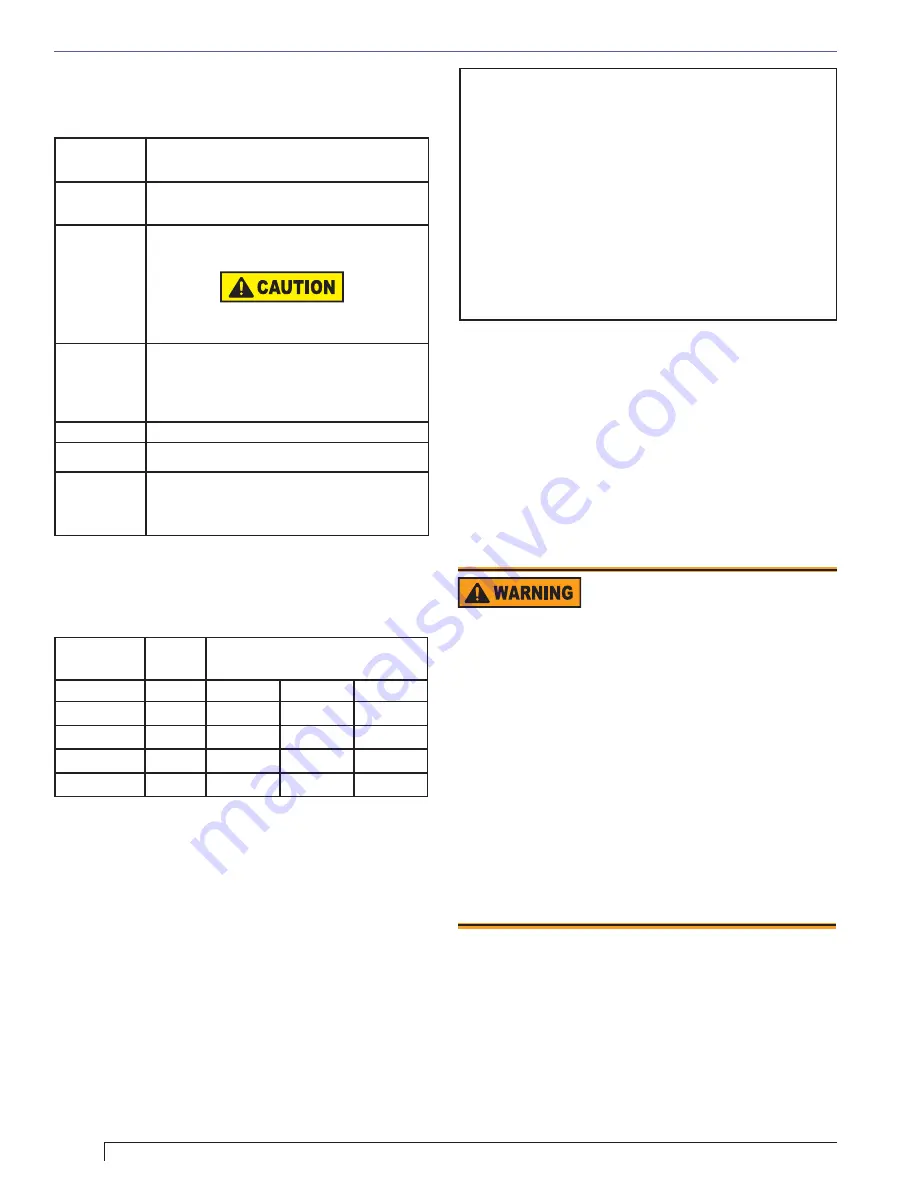

Table 3. – Air Tube Combinations (ATC)

Firing rate

(gph)

Head

ATC codes for usable air tube

lengths:

(min-max)

5”

7”

9”

0.40-1.35

9-Slot

NX50LB

NX70LB

NX90LB

0.40-1.35

6-Slot

NX50LC

NX70LC

NX90LC

1.10-1.75

9-Slot

NX50LD

NX70LD

NX90LD

1.10-1.75

6-Slot

NX50LF

NX70LF

NX90LF

Inspect/Prepare

Installation Site

Clearances to Burner and Appliance

Provide space around burner and appliance for ease

of service and maintenance. Check the minimum

clearances against those shown by the appliance

manufacturer and by applicable building codes.

Inspect Chimney or Direct Vent System

General Information

Table 2. – Burner Specifi cations

Capacity

LB & LC

Firing rate: 0.40 – 1.35 GPH

Input: 56,000 – 189,000 Btu

Capacity

LD & LF

Firing rate: 1.10 - 1.75 GPH

Input: 154,000 – 245,000 Btu/h

Fuels

U. S.

No. 1 or No. 2 heating oil only (ASTM D396)

Canada

No. 1 stove oil or No. 2 furnace oil only

Electrical

Power supply:

120 VAC, 60 Hz, single phase

Operating load:

5.8 Amps max

Motor:

1/7 hp, 3450 rpm, NEMA 48M frame

PSC rotation CCW when facing shaft end

Ignition:

Continuous duty solid-state igniter

Fuel pump

Outlet pressure - See Note 1

Air tube

ATC code - See Table 3

Dimensions

(with cover)

Height (maximum): 12-1/2 inches

Width (maximum): .15 inches

Depth: 9-1/4 inches

Air tube diameter: 3-1/4 inches

*

Note 1. See appliance manufacturer’s burner specifi cations for recom-

mended outlet pressure.

DO NOT USE GASOLINE, CRANKCASE

OIL, OR ANY OIL CONTAINING GASOLINE.

Carefully inspect the chimney or exhaust vent

system.

Make sure it is properly sized and in good working

condition.

Follow the instructions supplied by the appliance

manufacturer.

The installation must strictly comply with all

applicable codes, authorities having jurisdiction and

the latest revision of the National Fire Protection

Association Standard NFPA 31 for the installation of

chimneys and vent sizing, (or CSA-B139 and CSA-

B140 in Canada).

Regulation by these authorities take precedence

over the general instructions provided in this

installation manual.

y

y

y

y

y

Fire, Smoke & Asphyxiation

Hazard

Section: General Information & Inspect/Prepare Installation SIte

Summary of Contents for UO-3 CV

Page 2: ...2...