hçãéäÉííJ_~ìë~íò=^Åíêçë=

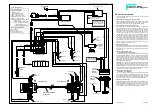

cÉêíáÖëíÉääìåÖ=ÇÉê=_~ìÖêìééÉå

`çãéäÉíÉ=háí==^`qolp=

`çãéäÉíáçå=çÑ=~ëëÉãÄäó=Öêçìéë

1387

109

109

114

114

1017

1

12

12

12

12

12

1

1018

222

1022

1

1

1025

1025

1016

1019

1021

1020

15

15

355

355

1

1

1

1

1

80-e.DOC / K-Actros

Page 6

T

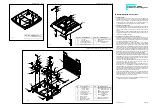

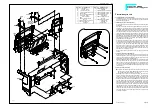

^ëëÉãÄäáåÖ=íÜÉ=Å~Ä=

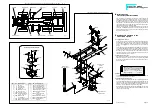

7.1 Cutting threads (see small drawing)

Threads have to be cut into eight screw holes on the front panel. Use

self-cutting screws 111 to cut these threads by the same method as

described under chapter 4.1.

7.2 Mounting the front- and side panels

Don't tighten all screwed connections as the cab skeleton has still to

be adjusted.

Start by securing the left-hand fixing plate 1020 into the suiting cut-

out made for this purpose on the front panel 1016; use countersunk

screw 355, serrated washer 15 and nut M3 for that. Afterwards slide

two square nuts 12 into both upper slots on the fixing frames of the

left side panel 1017; then fix the side panel with screws 1 onto the

fixing plate. Make sure that the external sides of both, front- and side

panels, are exactly in alignment. Now mount the right-hand fixing

plate 1021 and the right-hand side panel 1018 in the same way. Slide

another square nut 12 into each of the rear upper fixing slots on the

side panels; with screws 1 secure then the fixing angle 1022 into

place between the two side panels.

At this stage of assembly adjust the external contours of the pre-

mounted cab with the roof assembled at chapter 4.1. From top slide

that rear panel you have already mounted onto the roof into the verti-

cal grooves on the side panels. Both lateral fixing plates mounted

onto the cab, as well as the fixing angle include fixing holes; these

holes have to be aligned with those pilots which previously were

added to the roof. At the screwed connections on the panels all com-

ponents may now suitably be moved.

Once all parts have been adjusted correctly, tighten all nuts and

screws.

7.3 Doors, windscreen and dashboard

Set the doors you have assembled at stage 3.2 into their places on

the cab. With screws 1 fix the hinge supports to the front panel. When

closed, the doors should stay parallel to the side panel; by moving

the supports you achieve the final adjustment.

Press the windscreen 1019 into the front panel. For this purpose slide

the screen from inside into the groove on the left side of the front

panel. In order to fit the screen into the groove on the right hand side

you need to bow it inwards slightly, then press it forward gently until

it clicks into place. Finally attach the dashboard with screws 1 onto

the front panel.

7.4 Seat- and lower rear panel

First pass the switch toggles at the switch panel through the holes

provided in the seat rear panel 222; secure from the front using

four knurled nuts 210 (see therefore illustration 14).

Attach the switch sticker onto the seat rear panel - above the four

holes for the toggle switches on the switch panel - ; the letters indi-

cating the switches are now upside down. Slide one square nut 12

into each of the slots on the centre fixing frames of the side panels.

Afterwards attach the seat rear panel 222 that way that those sides

with the fixing holes lay underneath the fixing frames on the side

panels; insert screws 1 from the bottom and tighten them on the right

side. Don't tighten the screws on the left-hand side as the left side

panel has still to remain moveable. With screws 114 and nuts 109 fix

the stopping devices for the cab lock 1025 onto the lower rear panel

1387. Slide the lower rear panel into the suiting groove on the right

side panel, press then the left side panel outwards and slide the rear

panel also into same groove. Now tighten the screws on the left side

on the seat rear panel.

Assembling the cab ill. 7

Qty.

No. Assembly part

2

--- Nut M3

16

1 Screw M3 x 6

10

12 Square nut M3

2

15 Serrated washer A 3.2

4

109 Nut M2

2

111 Self-cutting screw M3 x 8

4

114 Screw M2 x 6

1

222 Seat rear panel

2

355 Countersunk screw

M3 x 8

1

1016 Front panel ACTROS

1

1017 Side panel, -lh-

ACTROS

Qty.

No. Assembly part

1

1018 Side panel, -rh-

ACTROS

1

1019 Windscreen ACTROS

1

1020 Fixing plate for front, -lh-

1

1021 Fixing plate for front, -rh-

1

1022 Fixing angle for

side panels

2

1025 Stopping device for

cab lock

1

1387 Rear panel, bottom

Complete Kit

ACTROS. “C“

--- Switch sticker

B-80-4

Break the

inner edge at

the bottom

B-233-1