`çãéäÉíÉ=háí==^`qolp=

`çãéäÉíáçå=çÑ=~ëëÉãÄäó=Öêçìéë

64

62

13

13

949

949

1056

1056

54

54

2

60

61

63

59

708

359

2

13

2

58

391

1582

109

1044

653

654

6

1039

1041

1045

653

654

115

1042

2

1043

1039

NP

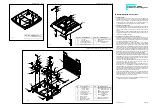

aêáîÉ=ëÉÅíáçå=

13.1 Mounting the motor and gearbox

Use screws 2 to bolt the gear cover 59 to the motor 708 (we supply

the white motor pinion 60 (14t.) already mounted to the motor shaft).

Before assembling the gearing lubricate the gears and shafts lightly

with Vaseline. Then clip the joint ball 64 in the gear wheel 62. Lay this

gear wheel, the double pinion 61 with shaft 63 and -not to forget!- the

shim 391 in the gear housing 58 and use screws 2 and M3 nuts to

secure the gear housing to the cover. Once assembled, this unit is

inserted from above into the opening in the frame and secured at the

sides with screws 2, washers 13 and M3 nuts. At the same time the

drive shaft 359 is inserted at the joint balls between the gearbox and

the differential.

13.2 Mounting the speed controller

When affixing the speed controller 1582 please ensure that the

ribbon cable with the two lamp PCBs are located between the

frame and the screws used to affix the speed controller (ill. 8).

First mount each of the straight ends of the clamp fittings 54 along

with the tank supports 1056 to the right-hand side of the frame; for this

purpose use screws 949 and nuts M3.

Now set the speed controller into the tank supports. Lay the long ends

of the tank supports and the clamp fittings around the speed control-

ler and fix the clamp fittings from underneath to the screws using

washers 13 and nuts M3.

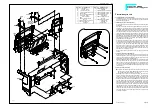

13.3 Mounting the exhaust unit

The threads in the plastic components are cut by the corresponding

screws; therefore before starting the assembly it is advisable first to

screw down them by approx. 2 mm and afterwards to unscrew them

again.

First press the outer exhaust panel 1040 into the slot on the lower

exhaust half shell 1042 and then mount the exhaust pipe 1043 with

one screw 57 and nut M3 (see small drawing).

Using screws 115 and nuts 109 fix the inner exhaust panel 1039 onto

the frame. Now fit the lower half shell along with the premounted

outer panel into the inner exhaust panel and screw down screws 6

but do not fasten them.

Lay the upper exhaust shield 1045 onto the upper exhaust half shell

1041, so that the narrow edge (approx. 2 mm) lays towards the frame;

connect both parts with screws 653 and nuts 654. For this purpose

use that plastic wrench 656 supplied with this kit. Afterwards slide

this premounted half shell into the inner exhaust panel; with it's slot

set it suitably onto the outer exhaust panel. Once all components fit

correctly, tighten screws

Finally add the front exhaust shield 1044 and fix it with four screws

653.

80-e.DOC / K-Actros

Page 10

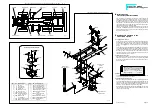

Drive section ill. 13

Qty.

No. Assembly part

11

--- Nut M3

9

2 Screw M3 x 8

2

6 Screw M3 x 25

4

13 Washer 3.2

2

54 Clamp fitting,

standard frame

1

57 Screw M3 x 10

1

58 Case for gear 116

1

59 Cap for gear 116

(1)

60 Motor pinion white,

14teeth

1

61 Double pinion

1

62 Gear wheel with

joint socket

1

63 Shaft for gear 116

1

64 Ball joint

2

109 Nut M2

2

115 Screw M2 x 8

1

359 Drive shaft 145mm

8

653 Hex head screw

M1.6 x 4

Qty.

No. Assembly part

1

391 Shim 5 x 10 x 1

4

654 Nut M1.6

1

656 Socket wrench 3.2 / 2.5

1

708 Bühler motor including

14 teeth pinion

2

949 Screw M3 x 35

1

1039 Exhaust panel, inside

1

1040 Exhaust panel, outside

1

1041 Exhaust half shell, top

1

1042 Exhaust half shell,

bottom

1

1043 Exhaust pipe

1

1044 Exhaust shield, front

1

1045 Exhaust shield, top

2

1056 Tank support for

square tank

1

1582 Speed controller,

square tank

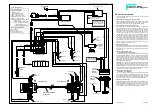

B-80-7a

B-80-7b

Brake light

green/yellow

to the radio receiver

to battery

B-460-2