`çãéäÉíÉ=háí==^`qolp=

`çãéäÉíáçå=çÑ=~ëëÉãÄäó=Öêçìéë

1030

929

760

723

655

13

26

2

2

26

13

655

2

2

13

57

176

176

1029

1388

1385

4

4

w

e

iß

g

rü

n

b

ra

u

n

720

721

721

722

719

724

564

564

80-e.DOC / K-Actros

Page 7

U

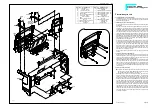

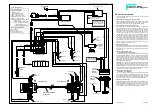

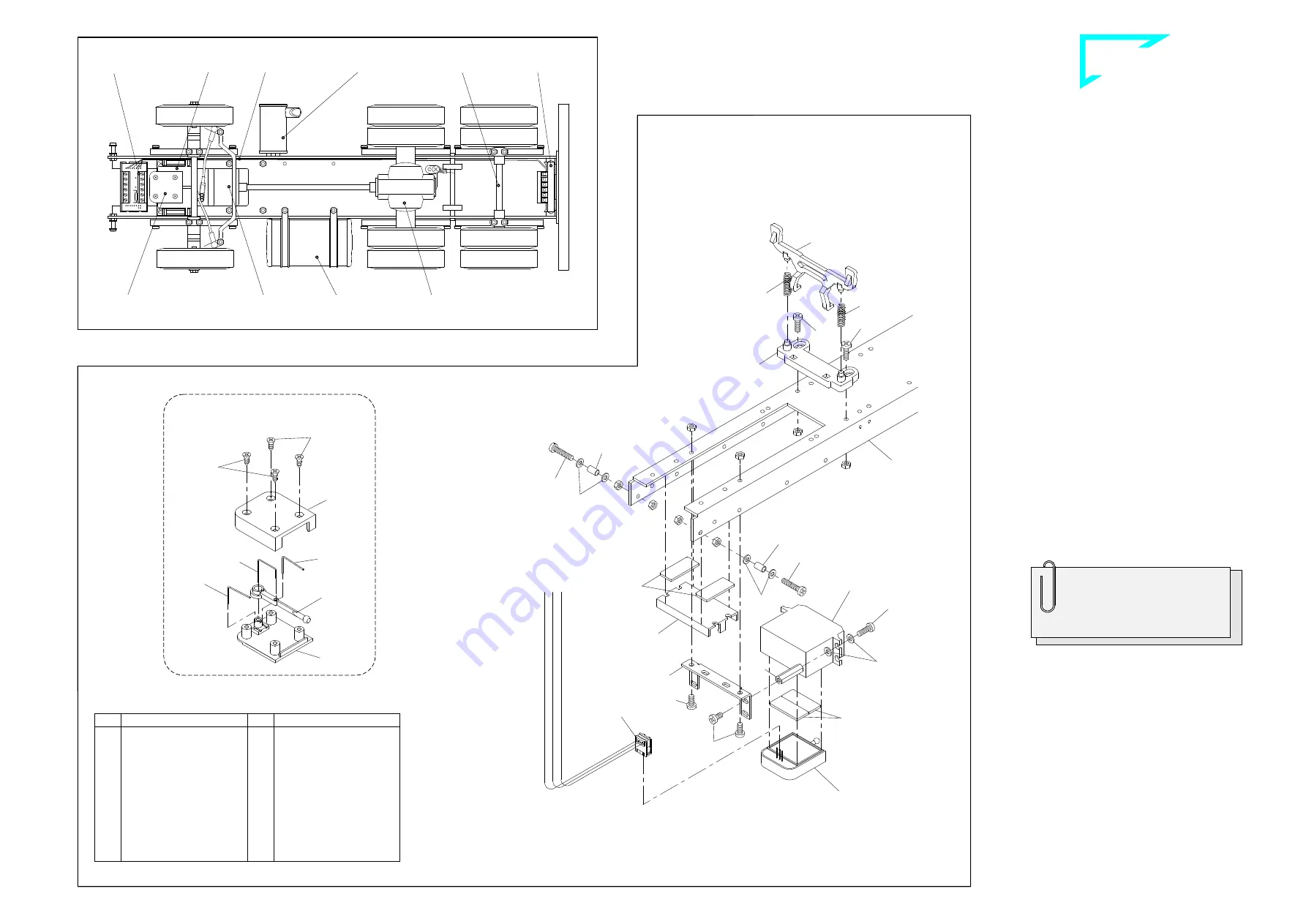

mêÉîáÉï=çÑ=íÜÉ==

ÉäÉÅíêáÅ~ä=ëóëíÉã=áåëí~ää~íáçå=

The illustration at the left shows the locations of the PCBs and the

routing of the ribbon cable beneath the frame. The cable will have to

be installed underneath the frame before the electrical devices are

installed in their entirety. The cable should run between the frame

and the axles, the fifth-wheel shaft and the screws used to affix the

tank. If the cable were to be laid later it would be necessary to disas-

semble some components already installed.

The best course of action is to read all the information on the electri-

cal system in Chapter 17 before you begin assembling the compo-

nents on the frame. This will give you an idea of which components

will be connected by cable.

V

`çãéçåÉåíë=~íí~ÅÜÉÇ=íç=íÜÉ==

Ñêçåí=Ñê~ãÉ=ëÉÅíáçå=

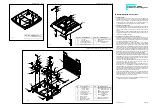

9.1 Fixing parts for the cab

Using each two nuts M3 to attach one screw 4, washer 13 and bush-

ing 26 onto the lower front holes on both sides of the frame 1388. At

a later stage of assembly (after the completion of all assembly

groups - see Chapter 16 - the front panel of the cab will be set

hereon.

Press the locking device 1029 into the base 1030 and set both pres-

sure springs 176 laterally between the pigots of these two parts. Ac-

cordingly to the illustration mount the base with screws 2 and nuts

M3 onto the frame. After adding the cab to the frame both noses of

the locking unit catch over those stopping devices mounted on the

rear panel and thereby secure the cab.

9.2 Mounting the servo unit

Accordingly to the drawing, use screws 57, washers 13 and bushings

1385 to fix the steering servo onto the servo supporting angle 760.

Use screws 2 and nuts M3 to attach the servo supporting angle un-

derneath the frame.

9.3 Mounting the PCB support

Use two adhesive pads 655 to affix the PCB support 723 behind the

servo supporting angle under the frame.

9.4 Assembling the blinker switch

Slide two single-bent springs 721 into the corresponding holes and

slots in the base plate 720. Insert the double-bent spring 722 into the

two holes on the lever blinker switch 724 and then place the eye of

the lever over the boss on the base plate. The cover plate 719 is now

secured to the base plate with countersunk screws 564.

Attach the blinker switch with two adhesive pads 655 that way onto

the steering servo, that the clamp-type connector 929 lays closely on

the fore edge of the housing.

Components attached to the front frame section ill. 9

View from below showing the location of components mounted onto the frame ill. 8

Moment of torsion of the servo should

be at 30 Ncm. The servo supporting angle

will fit servos with the following data:

L x W x H: ........................41 x 20 x 38 mm

Gauge for screwing ....................48

±

2 mm

Qty.

No. Assembly part

8

--- Nut M3

6

2 Screw M3 x 8

2

4 Screw M3 x 16

8

13 Washer 3.2

2

26 Bushing 4 x 0.5 x 7

2

57 Screw M3 x 10

2

176 Coil spring for lever

4

564 Countersunk tapping

screw 2.2 x 4.5

4

655 Adhesive pad,

double-sided

1

719 Cover for blinker switch

1

720 Base for blinker switch

Qty.

No. Assembly part

2

721 Spring, single bent

1

722 Spring, double bent

1

723 PCB support, small

1

724 Lever for blinker switch

1

760 Servo angle 1, small

1

929 Clamp-type connector,

3-pole

1

1029 Cab locking device

ACTROS

1

1030 Cab base ACTROS

2

1385 Threaded bushing 18mm

1

1388 Frame ACTROS,

432mm

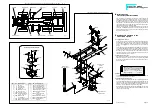

Assembly of blinker switch

Blinker switch Gear Speed controller Differential

B-80-6

Ribbon cable

from the switch

Steering servo

(not incl.

in the kit)

fully assembled

blinker switch

Front PCB Steering servo Ribbon cable Exhaust unit Rear axle Rear PCB

g

re

e

n

b

ro

w

n

w

h

it

e

B-80-5