830872-0001 REV 12/07/2022

©Copyright 2022 Wayne Dalton, a division of Overhead Door Corporation

21

16. CLUTCH ADJUSTMENT

NOTE:

The clutch is intended to provide protection for the door, the operator and associated

equipment. It is not intended for entrapment protection.

To Adjust the Clutch: Figure 32

• Decrease the compression on the clutch until the operator will not lift the door.

• Turning the adjustment castle nut counter-clockwise will decrease compression and clockwise

will increase compression.

• Gradually increase compression until the operator will perform a complete open and close cycle

without clutch slippage.

• Insert a cotter pin through the adjustment castle nut and bend a leg of the cotter pin to hold it

in place.

NOTE:

Periodically check the system for proper clutch action. If clutch starts to slip after working

properly for some time , check manual operation of door BEFORE adjusting clutch. The door may not

be operating freely or the counterbalance spring may need adjusting. Repairs and adjustments must

be performed by a trained service representative using proper tools and instructions.

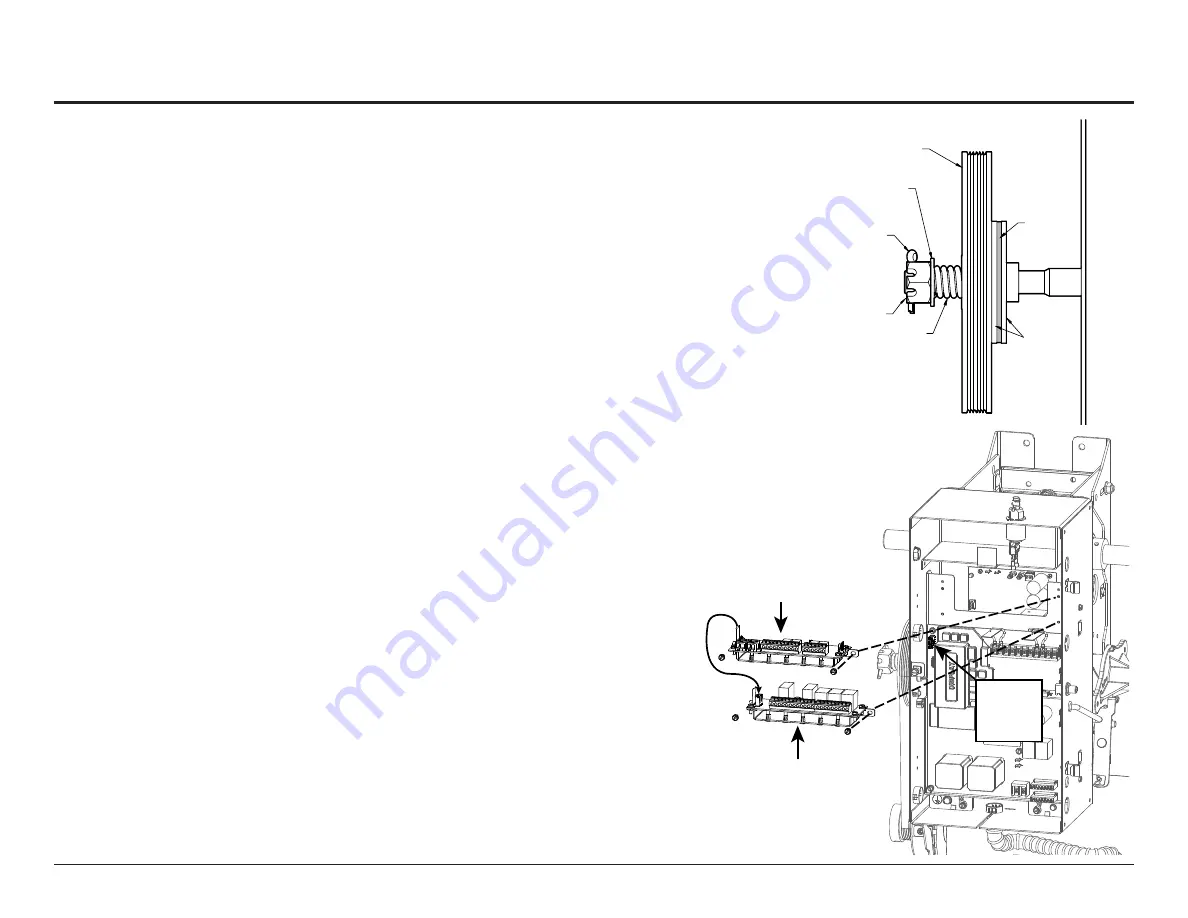

OPTIONAL AUXILIARY BOARD (AOM OR TCM)

Only one auxiliary board can be used with this opener.

• Unplug FDO module ribbon harness from main control board plug connector.

See Figure 33

• Remove the two screws mounting the FDO module to plate.

• Use the two screws included with the auxiliary board and mount to plate where FDO

module was.

• Plug auxiliary board ribbon harness into plug connector on main control board.

• Reinstall FDO module onto plate just above the auxiliary board.

• Plug FDO module ribbon harness into connector on auxiliary board.

NOTE:

Additional menu items will appear during programming. See the instructions

included with the Auxiliary board to see changes.

4.10

Clutch Adjustment

NOTE:

Additional menu items will appear

during programming. See the instructions

included with the Auxiliary board to see

changes.

To Adjust the Clutch: Fig, 24

1) Decrease the compression on the clutch until the operator

will not lift the door.

•

Turning the adjustment castle nut counter-clockwise

will decrease compression and clockwise will increase

compression.

2) Gradually increase compression until the operator will

perform a complete open and close cycle without clutch

slippage.

3) Insert a cotter pin through the adjustment castle nut and

bend a leg of the cotter pin to hold it in place.

NOTE:

The clutch is intended to provide protection for the door,

the operator and associated equipment. It is not intended for

entrapment protection.

NOTE:

Periodically check the system for proper clutch action.

If clutch starts to slip after working properly for some time ,

check manual operation of door BEFORE adjusting clutch. The door may not be operating freely or the

counterbalance spring may need adjusting. Repairs and adjustments must be performed by a trained

service representative using proper tools and instructions.

CLUTCH PULLEY

WASHER

COTTER PIN

ADJUSTING NUT

CLUTCH

PAD

CLUTCH

PLATE

SPRING

1) Unplug FDO module ribbon harness from main control board

plug connector. Fig. 25

2) Remove the two screws mounting the FDO module to plate.

3) Use the two screws included with the auxiliary board and

mount to plate where FDO module was.

4) Plug auxiliary board ribbon harness into plug connector on

main control board.

5) Reinstall FDO module onto plate just above the auxiliary

board.

6) Plug FDO module ribbon harness into connector on auxiliary

board.

Only one auxiliary board can be used with this opener.

Optional Auxiliary Board (AOM or TCM)

FDO Module

AUX Board

Ribbon

Harness

Plug

Section 4: Installation

Fig 24

Fig 25

4.10

Clutch Adjustment

NOTE:

Additional menu items will appear

during programming. See the instructions

included with the Auxiliary board to see

changes.

To Adjust the Clutch: Fig, 24

1) Decrease the compression on the clutch until the operator

will not lift the door.

•

Turning the adjustment castle nut counter-clockwise

will decrease compression and clockwise will increase

compression.

2) Gradually increase compression until the operator will

perform a complete open and close cycle without clutch

slippage.

3) Insert a cotter pin through the adjustment castle nut and

bend a leg of the cotter pin to hold it in place.

NOTE:

The clutch is intended to provide protection for the door,

the operator and associated equipment. It is not intended for

entrapment protection.

NOTE:

Periodically check the system for proper clutch action.

If clutch starts to slip after working properly for some time ,

check manual operation of door BEFORE adjusting clutch. The door may not be operating freely or the

counterbalance spring may need adjusting. Repairs and adjustments must be performed by a trained

service representative using proper tools and instructions.

CLUTCH PULLEY

WASHER

COTTER PIN

ADJUSTING NUT

CLUTCH

PAD

CLUTCH

PLATE

SPRING

1) Unplug FDO module ribbon harness from main control board

plug connector. Fig. 25

2) Remove the two screws mounting the FDO module to plate.

3) Use the two screws included with the auxiliary board and

mount to plate where FDO module was.

4) Plug auxiliary board ribbon harness into plug connector on

main control board.

5) Reinstall FDO module onto plate just above the auxiliary

board.

6) Plug FDO module ribbon harness into connector on auxiliary

board.

Only one auxiliary board can be used with this opener.

Optional Auxiliary Board (AOM or TCM)

FDO Module

AUX Board

Ribbon

Harness

Plug

Section 4: Installation

Fig 24

Fig 25

Figure 33

Figure 32

Operator Install (continued)