Page 3

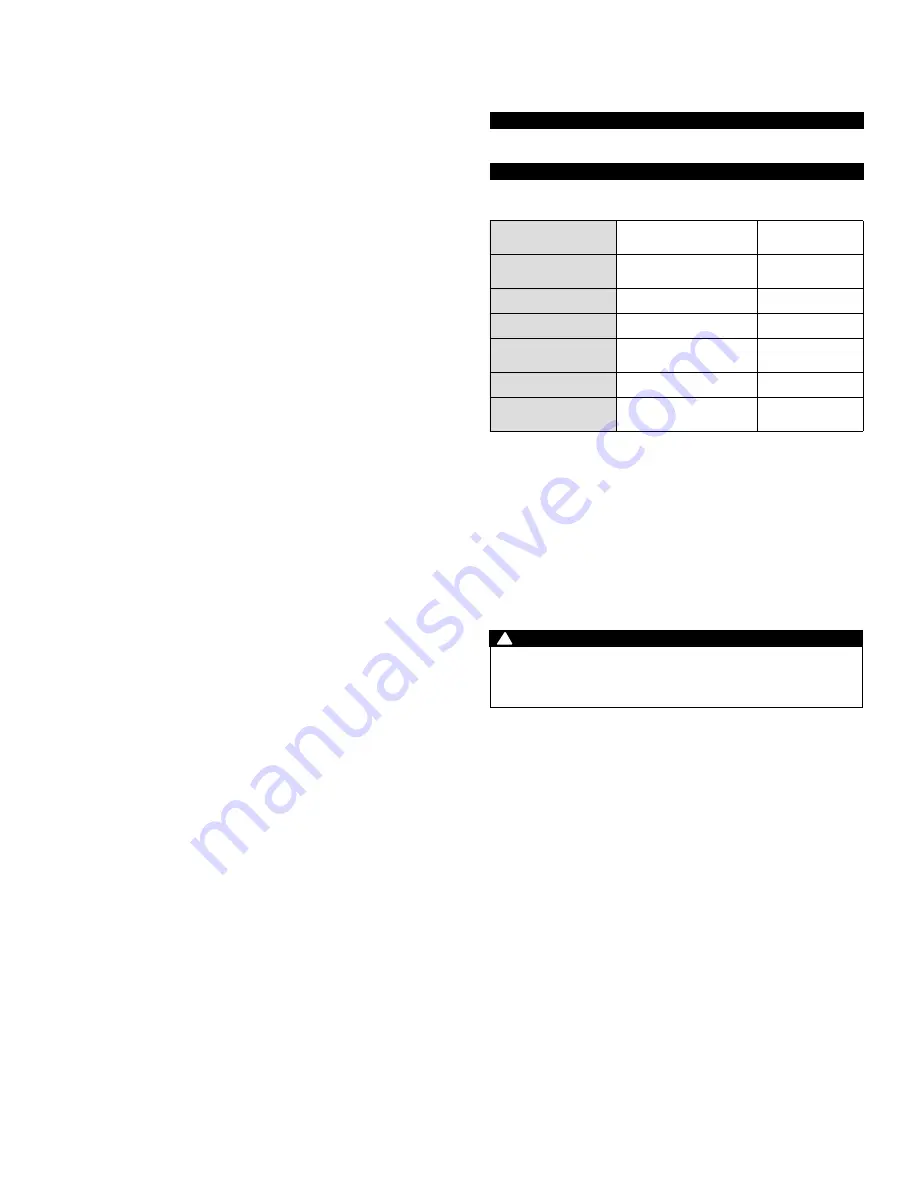

Operational Parameters

NOTICE

Installation must comply with state and local plumbing regulations.

Operating

Temperatures:

Maximum 100°F (37.8°C)

Minimum 40°F

(4.4°C)

Operating Pressure:

Maximum 100 psi (690 kPa)

Minimum 35 psi

(341 kPa)

pH Parameters:

Maximum 11

Minimum 2

Iron:

Maximum 0.2 ppm

TDS

(Total Dissolved Solids)

< 1800 ppm

Turbidity

< 5 NTU

Hardness

Maximum 10 Grains

Per Gallon *

Hardness:

Recommended hardness not to exceed 10 grains per

gallon, or 170 parts per million.

* System will operate with hardness over 10 grains but the

membrane life may be shortened. Addition of a water

softener may lengthen the membrane life.

Water Pressure:

The operating water pressure in your home

should be tested over a 24 hour period to attain the maximum

pressure. If the incoming water pressure is above 100 psi then a

water pressure regulator is required. A booster pump is needed

for incoming water pressure under 35 psi.

NOTICE

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operational Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation & Startup

Contents of Reverse Osmosis System. . . . . . . . . . . . . . . . . . 4

Recommended Tools For Installation . . . . . . . . . . . . . . . . . . . 4

Plumbing Diagram and Parts List. . . . . . . . . . . . . . . . . . . . . . 5

Drill a Hole for the Reverse Osmosis Faucet. . . . . . . . . . . . . . 6

How to use Quick Connect Fittings on Your RO System . . . . 6

Faucet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Adapt-a-Valve Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Drain Saddle Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Drain Saddle Tube Connection . . . . . . . . . . . . . . . . . . . . . . . 9

Tube Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Reverse Osmosis Module Mounting . . . . . . . . . . . . . . . . . . 10

Tank Ball Valve Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Blue Tube Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Start up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance & Troubleshooting

Membrane Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Changing The Filter Cartridges . . . . . . . . . . . . . . . . . . . . . . 11

Annual Sanitization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Check Air Pressure in the Tank . . . . . . . . . . . . . . . . . . . . . . 13

Procedure for Extended Non-Use (More than 2 months) . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Arsenic Fact Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Service Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Copper Tube: Reverse Osmosis water should not be run through

copper tube as the purity of the water will leach copper causing

an undesired taste in water and pin holes may form in the tube.

System is intended to be installed using the cold water supply only.

WARNING

!

Summary of Contents for H2O-DWRO300

Page 31: ...Page 31 ...

Page 49: ...Page 49 ...