Field Testing Procedure

FEBCO recommends the use of the appropriate test method

presented in the ASSE Series 5000 manual that is consistent with

the local codes.

Before starting the procedure, remove the freeze sensor mounting

clip from the test cock and set it aside to avoid damage. After the

procedure is finished, reattach the clip on either test cock.

Equipment Required

Sight Tube Test Kit (1" clear plastic Sight Tube about 40" long with

appropriate fittings to attach to test cocks of vacuum breaker)

Purpose of Test

To test the air inlet and the check valves for proper performance.

Test Air Inlet

The air inlet must be tested to verify opening above 1 psi.

(For visual aid information, see Figure 3.)

1. Remove the canopy from the top of the vacuum breaker to

expose the air inlet.

2. Install the sight tube at test cock No. 2.

3. Close ball valve B on the discharge side of the vacuum breaker.

4. Open test cock No. 2, fill the tube to about 30" above the poppet,

then close the test cock.

5. Close ball valve A on the inlet side of the vacuum breaker.

6. Slowly open test cock No. 2 while watching the poppet in the air

inlet. The poppet must unseat. If the air inlet does not open, it is

sticking and must be repaired.

7. Close test cock No. 2 and remove the sight tube.

Test Check Valve

The check valve must be tested to hold against 1 psi in the direction

of flow.

1. Install the sight tube at test cock No. 1.

2. Open ball valve A to allow the unit to refill with water.

3. Open test cock No. 1 and allow the sight tube to fill about 30"

above the top of the unit, then close the test cock.

4. Close ball valve A. (Ball valve B should already be closed.)

5. Open test cock No. 1.

6. Open test cock No. 2. Water may run from test cock No. 2 initially,

but should stop after a short time. The level of water in the sight

tube may drop a little, but should not drop below 28" above the

check valve. (Centerline of the discharge ball valve.) If the level in

the sight tube continues to drop and water continues to run out of

test cock No. 2, the check valve is leaking and must be repaired.

7. Close test cocks No. 1 and No. 2.

Restore Operation

Restore all valves and test cocks to the original positions and replace

the canopy.

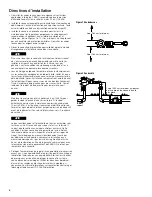

Figure 3

Canopy

Sight Tube

Test Cock

No. 1

Test Cock No. 2

Ball Valve A

Ball Valve B

3