Safety

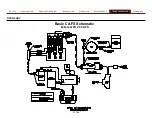

Introduction

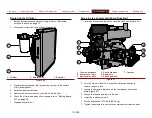

Product Overview

Installation

Operation

Maintenance

Troubleshooting

Warranty

31 | 44

Do not operate beyond

recommended pressure.

Liquid ejected at high

pressure can cause

serious injury.

High Pressure

•

•

Do not operate while all discharges or drains are closed. High

pressure will result and damage to the system, its components or

high pressure leaks could occur.

Do not enter reach into or

enter the compartment

when the equipment is on.

Rotating parts can cause

severe injury or death

Moving Parts

•

•

Rotating parts when the equipment is operating. Do not enter or

reach into the module while the equipment is running.

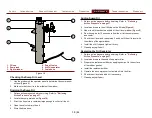

Operating the Panel Light

Press the panel light button to turn the panel lights on and off (

.

Selecting the Hose

Select a hose rated for CAFS use for best performance.

Selecting the Nozzle

You can use a variety of nozzle types and sizes to discharge compressed air

foam. Consider the following when selecting the nozzle:

•

Smooth bore nozzles provide best foam performance.

•

Smaller diameter nozzle tip produce a wetter foam and larger diameter

nozzle tip produce a dryer foam.

•

Fog nozzles tend to break down the foam structure making a wetter less

expansive foam.

Understanding the Waterway Valves

Use the valves to manage the water flow in the system. The valves perform the

following functions:

Tank to Pump Valve

• Controls whether the water source is the on-board tank or the suction

intake on the operator panel.

• Always operate the valve fully open or fully closed.

Clear Water Discharge Valve

•

Controls whether the water flows to the clear water outlet on the

operator panel.

• It is possible to operate the CAFS and clear water discharge given an

adequate water supply is flowing through the pump.

Tank fill

•

Allows water to flow from the suction in-take to fill the on-board tank.

• Allows water to recirculate to prevent the pump from overheating.

Summary of Contents for ECLIPSE CAFSystem 2.0

Page 2: ......