75

WPL 612 User Manual

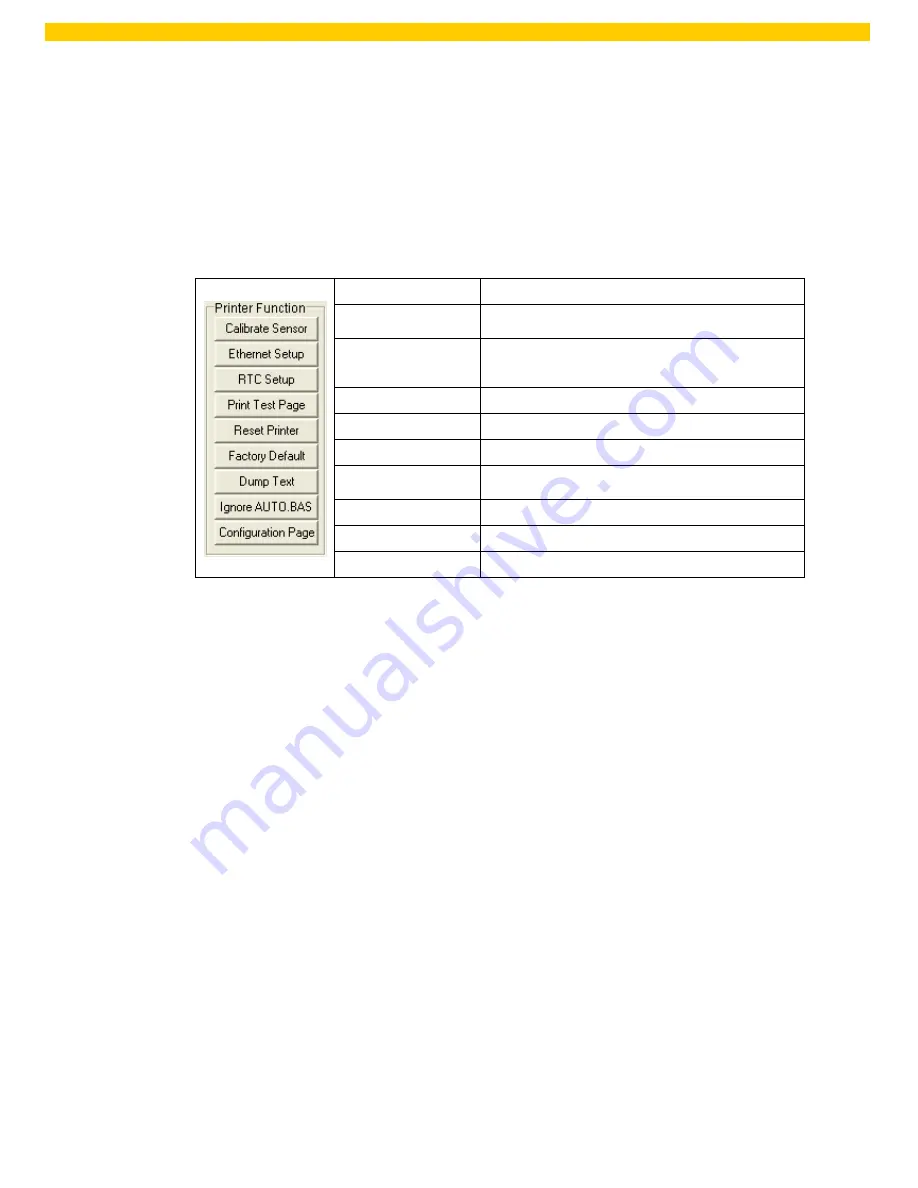

4.2 Printer Function

(Calibrate sensor, Ethernet setup, RTC setup………)

1. Select the PC interface connected with barcode printer.

2. Click the “Function” button to setting.

3. The detail functions in the Printer Function Group are listed as below.

Function

Description

Calibrate Sensor

Calibrate the sensor specified in the Printer Setup

group media sensor field

Ethernet Setup

Setup the IP address, subnet mask, gateway for

the on board Ethernet (Please refer to next

section)

RTC Time

Synchronize printer Real Time Clock with PC

Print Test Page

Print a test page

Reset Printer

Reboot printer

Factory Default

Initialize the printer and restore the settings to

factory default.

Dump Text

To activate the printer dump mode.

Ignore AUTO.BAS

Ignore the downloaded AUTO.BAS program

Configuration Page

Print printer configuration

Note:

For more information about Diagnostic Tool, please refer to the diagnostic utility quick start

guide in the CD disk \ Utilities directory.