16

OPERATIONS

NOTE: This operations section was designed to give instructions on the basic operations of this

lathe. It is strongly recommended that you read books, trade magazines, or get formal training to

maximize the potential of your lathe while minimizing the risks.

ADJUSTING THE TOOL REST

The tool rest should be positioned as close as possible

to the workpiece. It should be 1/8” below

the centerline of the workpiece. Rotate the workpiece by hand to make certain you have proper

clearance.

WARNING!

MAKE CERTAIN THAT THE MACHINE IS DISCONNECTED FROM THE POWER

SOURCE.

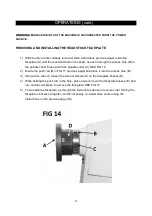

1)

Position the banjo (A) on the bed by loosening the banjo lock handle (B) and sliding the

banjo to the desired position. Tighten handle (B) to lock in place. SEE FIG 5

2)

Adjust the height of the tool rest (C) by loosening the tool rest lock handle (D) and raising

or lowering the tool rest. Tighten handle (D) to lock in place. SEE FIG 5

ADJUSTING BANJO / TAILSTOCK CLAMPING PRESSURE

The clamping device on the banjo and tailstock are set at the factory and should not need

adjustment. However, if adjustment is necessary, see instructions below.

1)

Loosen clamping handle and slide the tailstock or banjo off the end of the bed. Tighten or

loosen the nut beneath the tailstock or banjo and reinstall on bed. Test clamping pressure

and repeat if necessary.

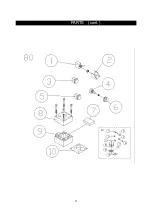

Summary of Contents for 60170ML-WHD

Page 5: ...5 FEATURE IDENTIFICATION cont WIRED REMOTE CONTROL WITH MAGNETIC BACK...

Page 24: ...24 PARTS...

Page 25: ...25 PARTS cont...

Page 31: ...31 WIRING DIAGRAM...

Page 32: ...32...