245.805.011

35

Date: 2021-12-09

Life of the wire

It is Wahlberg Motion Design policy to apply the strictest possible calibration procedures and use the

best quality materials available to ensure optimum performance and the longest possible component

lifetimes. However, wires are subject to wear and tear over the life of the product, resulting in special

attention to the state of the wire. The extent of wear and tear depends heavily on operating conditions

and environment, so it is impossible to specify precisely whether and to what extent the wire

performance will be affected.

The expected lifetime of the wire depends on the load and travel length as well as duty cycle.

Wire discard criteria

When the wire is exposed, the following guidelines can be used to control whether the wire must be

discarded. The following serves as guidelines and if any of the discard criteria are reached, the winch

must immediately be taken out of service, and the wire replaced, before using the winch again.

The wire should be discarded when:

When the overall diameter of the is reduced by 8 %, or the outer wires have lost its diameter by

33 % through wear. This reduction in diameter of the is measured on a portion of the which has

been subjected to abrasion and stresses with respect to the portion of the which is subjected to

stresses but not abrasion e.g. portions near drum or anchorage.

When there is evidence of considerable plastic wear or surface embrittlement.

When the diameter of the wire has suddenly reduced, or the lay length has suddenly increased

or decreased.

When there is evidence of severe corrosion like chain pitting.

When there is any evidence of internal corrosion in the rope. This can be recognized by slackness

of outer wires due to the internal wires corroding away.

When the wire has been subjected to mechanical damage, crushing, kink, bends, bird cage, etc.

When the core of the wire has collapsed.

When the wire has been subjected to a high temperature or heat due to fire.

When the wire has been subjected to severe shock load or overload due to an accident with the

winch.

Figure 2: When using a calliper to measure wire diameter, measure from crown to

crown, not from valley to valley.

Summary of Contents for 50 Series

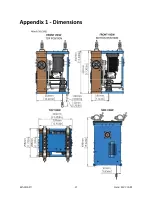

Page 37: ...245 805 011 37 Date 2021 12 09 Winch 50 245...

Page 38: ...245 805 011 38 Date 2021 12 09 Winch 50 Double 246 701...

Page 39: ...245 805 011 39 Date 2021 12 09 Winch 50 Double Power and Cat5 246 704...

Page 40: ...245 805 011 40 Date 2021 12 09...

Page 41: ...245 805 011 41 Date 2021 12 09...

Page 43: ...245 805 011 43 Date 2021 12 09 This page is intentionally left blank...