48

HC 35 E • HC 45 E • HC 55 E

g

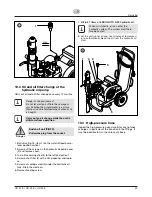

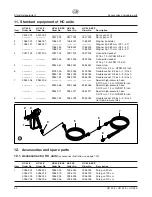

10.2 Checking the oil level in the

hydraulic oil tank

1. Turn oil measuring stick (fig. 17, item 1) to the left and

pull out.

2. The oil level should be visible between the marking

(see arrows) on the oil measuring stick.

3. If necessary, refill oil. For information on the oil grade,

refer to the oil change section, chapter 10.3.

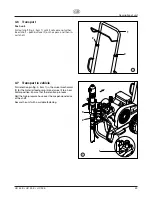

10. Servicing

10.1 General servicing

Servicing of the unit should be carried out once

annually by the WAGNER service.

1. Check high-pressure hoses, device connecting

line and plug for damage.

2. Check the inlet and outlet vents for wear.

3. Check oil level in hydraulic oil tank.

4. Carry out an oil change if necessary.

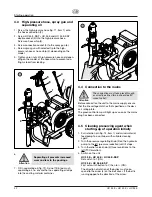

Check oil level daily

i

Danger

Switch off unit

A

(OFF).

Pull mains plug from the socket.

Remedy in case of faults

Servicing

Piston rod moves up and

down quickly.

Piston rod moves up and

down slowly when the

spray gun is closed.

Not enough pressure to

the spray gun.

Piston rod sputters when

stroking upward or down-

ward.

Suction tube projects over

the fluid level and sucks in

air.

Coating material viscosity is

too high, preventing it from

being sucked up.

Ball in inlet valve housing is

stuck.

Loose connections.

Relief valve is not closed

completely.

Relief valve worn.

Lower packing worn.

Ball in inlet valve housing

and ball in outlet valve seat

are not sealing properly.

Tip is worn.

Filter cartridge in high-

pressure filter is clogged.

High-pressure hose is too

long.

Solvent has made the upper

packing expand.

Refill the coating material

Thin out the coating material according to manufactu-

rer’s instructions.

Vent air from material feed pump and turn the relief

valve knob to the left (

k

Circulation).

Dismantle inlet valve housing, clean ball and valve

seat. Check all connections between the material feed

pump and spray gun.

Turn relief valve knob to the right (

p

spray).

Replace

If the measures described above do not help, replace

lower packing.

Dismantle inlet valve housing and outlet valve seat.

Clean balls and valve seats.

Replace

Clean or replace the filter cartridge.

Reduce length.

Replace upper packing.

Type of malfunction

Possible cause

Measure for elimination of malfunction