46

HC 35 E • HC 45 E • HC 55 E

g

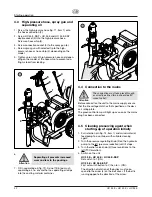

Hydraulic motor stuck

in the lower position.

Outlet valve seat in the

material feed pump is

loose.

Reversing valve in the

hydraulic motor is stuck

or the upper or lower he-

xagonal nut on the valve

rod has become loose.

Ball valve on the material feed pump – lever position

vertical. Screw out sealing screw on hydraulic motor.

Press down reversing valve on hydraulic motor. Remo-

unt sealing screw. Start unit. The piston rod moves

upward and then gets stuck in the lower position. The

cause is a loose outlet valve seat.

Problem to be solved by Wagner personnel.

Problem to be solved by Wagner personnel.

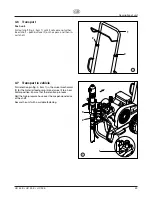

9.2 Hydraulic motor

Type of malfunction

Possible cause

Measure for elimination of malfunction

Cleaning the unit (shutting down)

Remedy in case of faults

9. Remedy in case of faults

9.1 Electric motor

Unit does not start

HC-55 E, HC 55 E-SSP

(400 V)

Piston rod in the material

feed pump is not moving

up and down.

Control lamp does not indi-

cate operational readiness.

No voltage.

The unit switches off auto-

matically in case of overloa-

ding.

The unit does not switch

on again independently.

Direction of rotation of

electric motor is incorrect.

Check voltage supply.

Switch the unit back on after 2 – 3 minutes.

Turn polarity changer in power plug by 180°.

Type of malfunction

Possible cause

Measure for elimination of malfunction

Made in Germany

ma

x.

39

00

ps

i

2

70

ba

r

G1

2

1

2

3

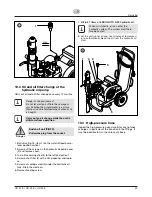

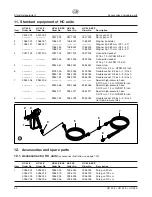

Intake filter in Airless spray gun

Dismounting (fig. 16)

1.

Pull protective guard (1) forward vigorously.

2.

Screw grip (2) out of the gun housing. Remove

intake filter (3).

3.

Intake filter congested or defective – replace.

Mounting

1.

Place intake filter (3) with the long cone into the gun

housing.

2.

Screw in grip (2) into the gun housing and tighten.

3.

Slot in protective guard (1).