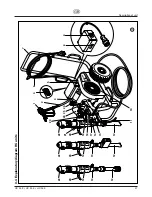

HC 35 E • HC 45 E • HC 55 E

45

g

Cleaning the unit (shutting down)

8.2

Suction filter with HC 35 E

–

Screw off the filter (fig. 14) from suction pipe.

–

Clean or replace the filter.

Carry out cleaning with a hard brush and an appro-

priate cleaning agent.

2. Insert O-ring (6) into the housing (8).

3. Insert filter cartridge (3).

4. Place thin seal (5) on threaded section of housing (8).

5. Place thick seal (4) on top of thin seal (5).

6. Slide pressure spring (2) onto housing cover pin (2).

7. Screw on housing cover (1) and tighten by hand.

1

2

3

4

5

6

7

8

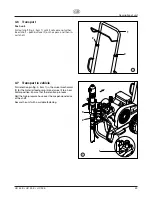

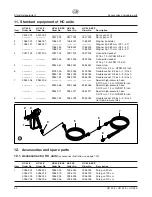

8.4 Cleaning Airless spray gun

–

Rinse Airless spray gun with an appropriate clea-

ning agent.

–

Clean tip thoroughly with appropriate cleaning

agent so that no coating material residue remains.

–

Thoroughly clean the outside of the Airless spray

gun.

A clean suction filter always guarantees

maximum feed quantity, constant spraying

pressure and problem-free functioning

of the unit.

i

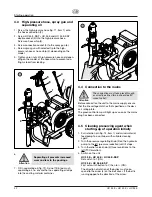

8.3

Cleaning the high-pressure filter

Clean the filter cartridge regularly.

A soiled or clogged high-pressure filter can cause a poor

spray pattern or a clogged tip.

Dismounting

1. Close ball valve on material feed pump – lever

position horizontal.

Flow of hydraulic oil to hydraulic motor of material

feed pump is interrupted.

2. Turn the relief valve knob three revolutions to the left

(

k

Circulation).

3. Switch off unit O (OFF).

4. Unscrew the housing cover (fig. 15, item 1).

5. Pull filter cartridge (3) out of housing (8).

6. Clean the pressure spring (2) and filter cartridge (3)

with an appropriate cleaning agent, clean the inside

of the housing (8) and housing cover (1).

7. Check ball in the filter cartridge (3) for wear and

replace filter cartridge, if necessary.

8. If ball in filter cartridge (3) is thoroughly worn, dismo-

unt O-ring (6) and valve seat (7). Replace worn valve

seat, if necessary.

9.

Always replace O-ring (6) after replacement.

10. Pull off pressure spring (2) from housing cover (1).

Measure length of pressure spring, and replace if

shorter than 19 mm.

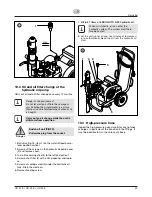

Mounting

1. Insert valve seat (7) with the ball seat surface facing

up into the housing (8).