44

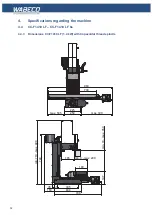

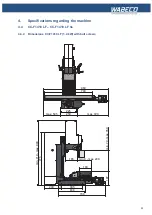

10. Feed motions of the X-, Y- and Z-axes

■

The longitudinal motion of the cross slide support (X-axis) is carried out by turning the hand wheel

(7).

■

The transverse motion of the cross slide support (Y-axis) is carried out by turning the hand wheel (9).

■

The feed motion of the boring and milling depth (Z-axis) is carried out via the hand wheel (3).

There are scale rings fitted to enable you to read off the distances.

One interval on the scale represents a distance of 0.05 mm. One full turn of the hand wheel is the same

as a skid distance

■ Scale ring

X-axis

(6)

with trapezoidal threaded spindle of 4 mm - with ball screws of 5 mm

■ Scale ring

Y-axis

(8)

with trapezoidal threaded spindle of 4 mm - with ball screws of 5 mm

■ Scale ring

Z-axis

(2)

with trapezoidal threaded spindle of 2 mm - with ball screws of 2.5 mm

Another option for moving the tool spindle is to use the rotation motion of the activation lever (4).

■

After undoing the clamping lever (1) the rotation motion may be executed.

■

One mark on the scale ring (5) represents a distance of 1 mm.

■

Then tighten the clamping lever (1) back up again.

■

The largest distance of the tool spindle is 55 mm.

It is recommended not to select a travel distance that is too big, instead, in the event of a greater depth,

you should use multiple passes to achieve the milling machine depth needed.

Summary of Contents for F1410 LF

Page 41: ...41 7 Fitting and removing the tools 42 6 Spannen und Ausdrücken der Werkzeuge 1 2 3 4 5 ...

Page 98: ...98 16 Drawings and legends 16 12 Spindle Z axis with ball screws 16 12 1 F1410 LF F1410 LF hs ...

Page 126: ...126 16 Drawings and legends 16 22 Support arm for control panel 1 2 3 4 5 6 8 9 5 4 7 9 8 ...