VMAC – Vehicle Mounted Air Compressors

Toll Free:

1-888-241-2289 Local: 1-250-740-3200

Fax: 1-250-740-3201

37

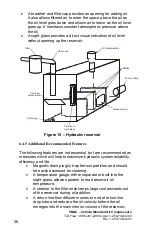

this is important on relatively small reservoirs (less than

about 1 gallon per GPM) where severe foaming and

aeration can occur if return line flow is not slowed prior to

tank entry.

•

A reservoir heater for preheating the hydraulic oil prior to

startup in extreme cold climate conditions.

6.4.6 Features Not Recommended

A suction screen or strainer is not recommended for mobile

equipment. The combination of long suction lines, cold startup

conditions and probable lack of strainer maintenance causes the

suction strainer to be more likely to promote pump damage (due to

cavitation) than it is to protect the pump.

A pressurized reservoir is not recommended for work trucks as it is

too sophisticated and provides too much potential for loss of overall

system reliability if it is not understood and not properly maintained.

6.5 Avoiding Cavitation

Pump cavitation may occur if the suction at the hydraulic pump inlet

exceeds 6 InHg (3psi) of vacuum relative to local atmospheric

pressure. Cavitation will severely reduce pump life & cause erratic

hydraulic system performance. Some steps to take to avoid pump

cavitation:

•

Mount the hydraulic oil tank as high above the pump as possible.

•

Keep the suction line as short as possible.

•

Avoid sharp 90 degree bends and sudden area changes in the

suction line wherever possible.

•

Keep all suction hose and fittings as large as possible.

•

If a suction line screen is used, be sure that it has sufficient high

flow rating.

•

If cold starting with the hydraulic oil at more than 2000 cSt (9200

SUS) viscosity, a no-load warm up interval should be used and a

pre-heater should be used on the tank and the suction line.

•

Wherever possible, use actual suction hose and thin walled barb

and clamp type fittings rather than high pressure hydraulic hose

and associated heavy walled fittings.

•

Make sure that the reservoir is of sufficient size