VMAC – Vehicle Mounted Air Compressors

Toll Free:

1-888-241-2289 Local: 1-250-740-3200

Fax: 1-250-740-3201

35

6.4.3 Material

Many reservoirs provided by PTO. pump suppliers are molded in one

piece from polyethylene. This is an excellent material choice from

the standpoint of weight, appearance, internal cleanliness, and low

leakage. If for any reason a custom reservoir is required, then

welded aluminum, steel or stainless steel are all good choices. The

inside of the reservoir must be thoroughly cleaned after all the

welding is completed. If plain steel is used, then the inner surface

should be coated with paint compatible with the hydraulic fluid.

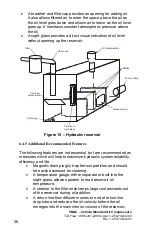

6.4.4 Essential Features

The hydraulic oil reservoir (Figure 15) should have the following

features.

•

The pump inlet line should be near the bottom of the

reservoir, well below the oil level and should protrude at

least 2” into the reservoir to keep it well clear of surfaces that

may collect contaminants.

•

Baffle plates should be use to prevent sloshing, to force the

flow to follow an indirect path from the return line to the

suction line in an S-shaped flow when viewed from above, to

promote cooling contact with walls, provide time for

deaeration and time for contaminants to drop out. They

should be notched or have a small end gap to the side wall

of reservoir, at opposite ends to produce an “S” shaped flow

pattern as viewed from above. The area of notches or end

gap should be at least two times the cross sectional area of

the suction line.

•

A drain plug, to facilitate draining of old hydraulic oil during

service, should be at the lowest point in the reservoir to

assure complete draining. It should be installed using an

adaptor or housing which does not protrude above the inner

surface of the floor of the tank. It should be visible and

accessible for removal, with sufficient space available for

catching the waste oil.

•

A return line drop tube is essential if the return line is

entering at or near the top of the tank. This minimizes

foaming, agitation and aeration of the oil, which is key to

system performance and pump reliability.

•

A return line filter provides the main protection against

system contaminants by removing small foreign particles

from the hydraulic oil and should be mounted external to the

reservoir for high visibility and easy service access.